Category: Controls

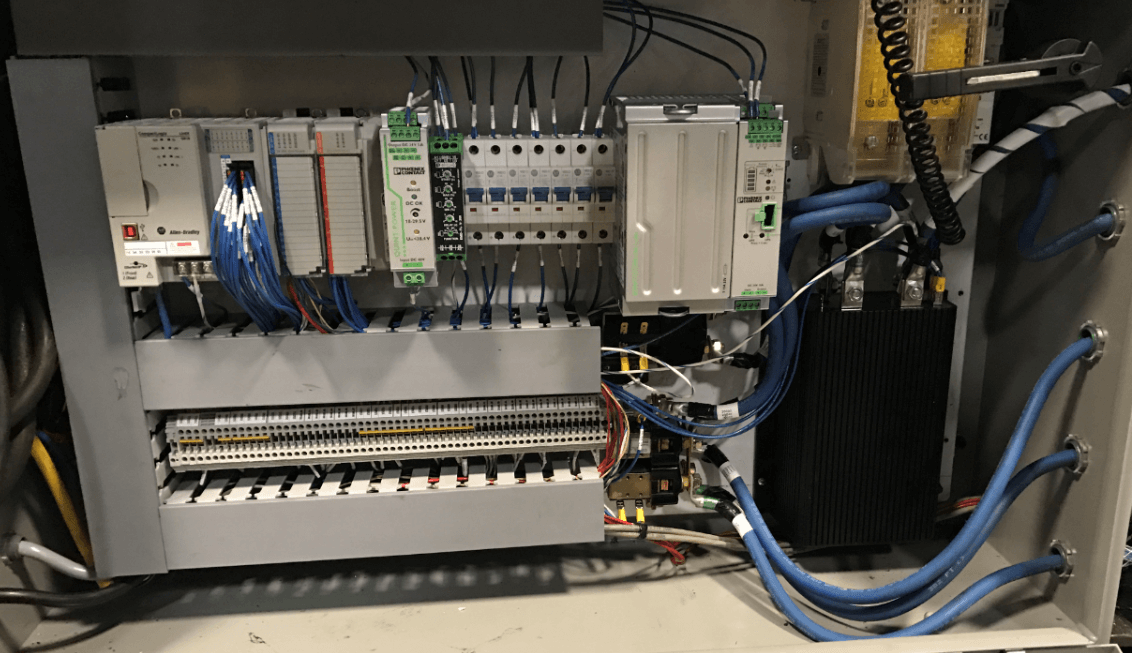

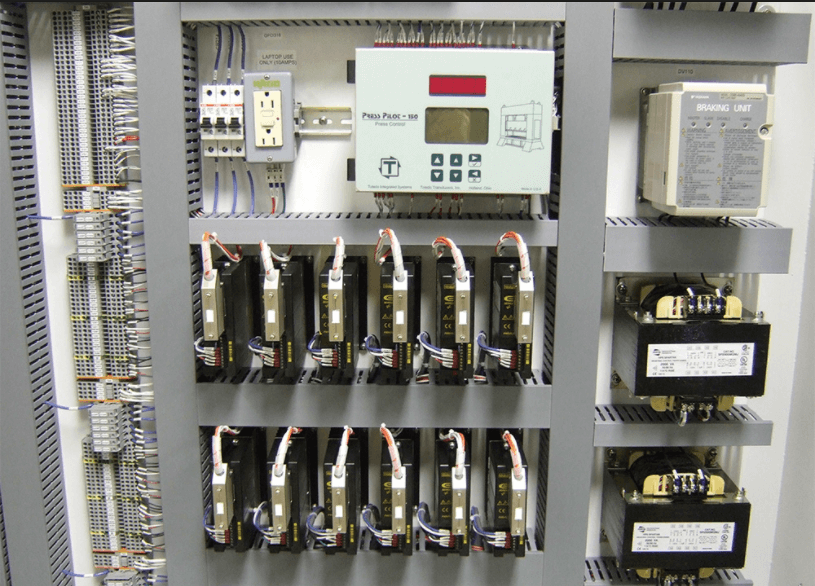

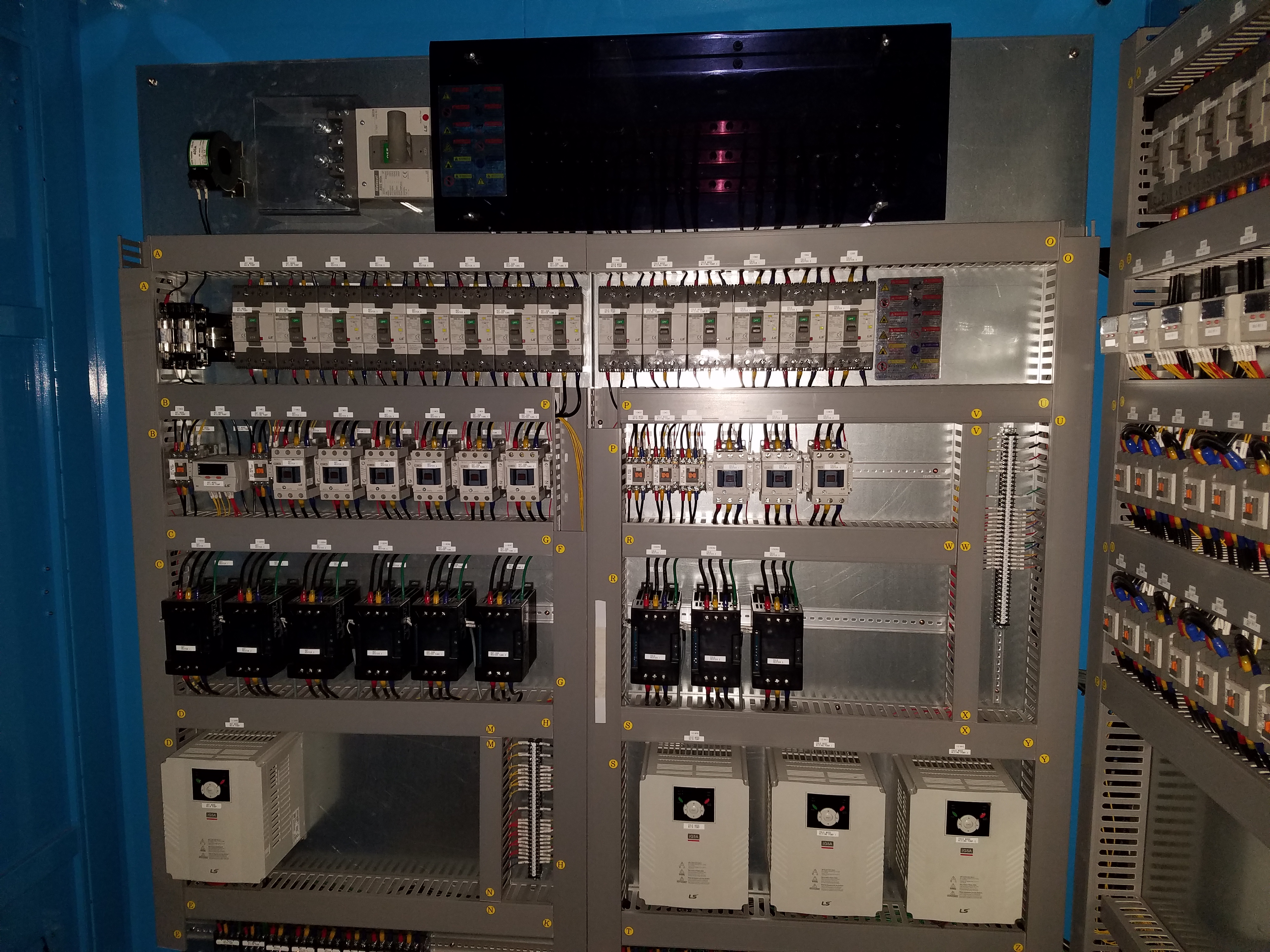

Many industries use PLCs to accurately time and program manufacturing operations. A PLC, or a programmable logic controller, is an industrial digital computer that has been adapted for use and control of manufacturing processes. It is built to withstand the harsh industrial environment of plants and factories such as intense temperatures, dampness, noise and other common disruptions.

The system is different from other controller communication systems because of its programmability and its widespread input/output array. It is easy to alter and modify a PLC’s program to fit each application’s constraint. The new PLC’s with Ethernet has greatly reduced the once time-consuming wiring process and with the low voltages used today has greatly reduced many of the electrical hazards.

A PLC comes with several distinctive functions like sequential control and ease of programming. This helps users to accurately time and program manufacturing operations. The system is based on logic controllers that are responsible for controlling and scrutinizing a large capacity of input and outputs for machine motion and operator safety.

Lee Contracting’s controls and robotics staff engineers have over 30 years of experience in the field. They have extensive knowledge of legacy systems and a comprehensive knowledge of many applications. In addition to supporting and upgrading older systems, we are fully up-to-date on the newest hardware and software platforms from all the major PLC suppliers. With our complete controls and robotics capabilities, Lee can handle the full programming of automation systems including all necessary design, development and engineering. Call today to receive a free quote, 888.833.8776.

Subscribe and receive updates via email

Automation of the manufacturing process can help a business to achieve high levels of productivity and efficiency while increasing product quality and profits. Automated manufacturing systems require little or no human participation to operate. These systems often perform the operations of assembling, processing, inspection, or handling of materials.

Here are 8 reasons why a company should consider implementing automation into their manufacturing process:

1. Increased Workplace Safety

Transferring some dangerous tasks to automated machines can make the workplace safer. Since the Occupational Safety and Health Act was signed into law in 1970, the safety and health of employees has become a priority. Automation has made the workplace safer for employees.

2. Reduced Labor Cost

Investing in automation can help to replace manual operations and thus, reduce increasing labor costs.

3. Increased Labor Productivity

Automated systems can perform tasks more efficiently than manual operations. Manufacturing process automation increases labor productivity and the total rate of production.

4. Reduced Manual Tasks

Automation can reduce several operations that are repetitive, tiring or boring for employees.

5. Accomplish Impossible Manual Tasks

There are certain manufacturing operations and processes that are not possible without the involvement of machines. Examples include rapid prototyping through graphic modeling, making of complex surfaces with Programmable Logic Controllers (PLC) or numerical controlled systems and integrated fabrication of circuits. These processes have special requirements for miniaturization, accuracy and geometry that are impossible to achieve manually.

6. Enhanced Product Quality

Automation reduces the fraction defect rate and automated operations are performed with greater conformity and uniformity.

7. Avoid Higher Costs of Not Automating

Automation benefits can lead to higher sales, better quality, improved productivity, a better bottom line due to higher efficiencies and a better company image. Companies that do not implement automation may find themselves lagging behind their competition who have chosen to automate.

8. Reduced Manufacturing Lead Time

Automation helps to reduce the elapsed time between the order of the customer and product delivery.

Lee Contracting’s controls & robotics engineers have over 30 years of experience. We specialize in press automation but are capable any type of automation from large stamping systems to stand-alone boring mills. Our controls design consists of hardware, software, control panel design, build and HMI screen development. We can accommodate any type of network, including Remote I/O, DeviceNet, Profinet and Ethernet or troubleshoot your existing relay logic system. We have experience in the following robotic brands: Fanuc, ABB and Motoman.

Our controls & robotics team can perform every aspect of your full turn-key automation.

Call today to receive a free quote (888) 833-8776.

Subscribe and receive updates via email

Lee Contracting is an industry leader when it comes to providing our customers with the best service in foundations, rigging, electrical, mechanical, fabrication, and maintenance & repair work. To support these departments, we also offer our customers the best in controls & robotics, building, roof-raising, emergency power, and storage. Learn more about each of our supplemental departments below:

Controls & Robotics

Lee’s controls and robotics staff have engineers with over 30 years of experience in the field, extensive knowledge of legacy systems and comprehensive knowledge of many applications. In addition to supporting and upgrading older systems, we are fully up-to-date on the newest hardware and software platforms from all the major PLC suppliers. With our complete controls and robotics capabilities, Lee can handle full programming of automation systems including all necessary design, development, and engineering.

Lee’s controls and robotics staff have engineers with over 30 years of experience in the field, extensive knowledge of legacy systems and comprehensive knowledge of many applications. In addition to supporting and upgrading older systems, we are fully up-to-date on the newest hardware and software platforms from all the major PLC suppliers. With our complete controls and robotics capabilities, Lee can handle full programming of automation systems including all necessary design, development, and engineering.

Building

The Lee Contracting building department specializes in design-build projects including: office renovations and expansions, production facility expansions, complete building construction, and all types of renovations utilizing all in-house trades to complete a turn-key project. Our teams work together with you to take your vision and make it a reality, while working within your timeline and controlling project costs. We have the skilled trades in-house providing you with a one-stop-shop and a superior product that suits your specific needs.

Roof Raising

If new equipment is too tall for your current building, you may be considering an addition. This is not your only option. Lee has the equipment and expertise necessary to lift your roof to the required height, allowing you to keep the footprint of your plant. At Lee, we can raise any part of your roof or even the entire roof to any height needed to accommodate your equipment. Using our unique methods and all in-house equipment, we can shorten the time frame of the project as well as work around ongoing plant processes.

If new equipment is too tall for your current building, you may be considering an addition. This is not your only option. Lee has the equipment and expertise necessary to lift your roof to the required height, allowing you to keep the footprint of your plant. At Lee, we can raise any part of your roof or even the entire roof to any height needed to accommodate your equipment. Using our unique methods and all in-house equipment, we can shorten the time frame of the project as well as work around ongoing plant processes.

Emergency Power

When the power goes out, and production is compromised, call on us to bring out one of our trailer mounted generators. Our emergency response crews will have you back up and running in no time. We can even set and install a permanent transfer switch complete with leads required for instant generator hook-up on your site.

Storage

At Lee, we understand that as your business grows, your storage needs will change. Our 300,000+ square foot facility provides a safe and secure venue for storing your physical assets. In addition, companies may utilize our facility for a myriad of other possibilities: erect a sample system for client presentations, set up a light production system for spare parts, or establish a satellite office. The possibilities are endless! Whether it be short-term or long-term storage, heavy or light industrial items, Lee can provide your company with a complete industrial storage solution.

At Lee, we understand that as your business grows, your storage needs will change. Our 300,000+ square foot facility provides a safe and secure venue for storing your physical assets. In addition, companies may utilize our facility for a myriad of other possibilities: erect a sample system for client presentations, set up a light production system for spare parts, or establish a satellite office. The possibilities are endless! Whether it be short-term or long-term storage, heavy or light industrial items, Lee can provide your company with a complete industrial storage solution.

These capabilities help Lee Contracting provide our customers with the complete package when it comes to their next project. For a free quote, call us at 888-833-8776 or you can request one online today.