Category: Electrical

Industrial electricians are trained personnel who test, troubleshoot, install and repair electrical components and systems in an industrial plant or worksite. Electricians also need to read and interpret blueprints and must remain current on electrical code specifications for the area.

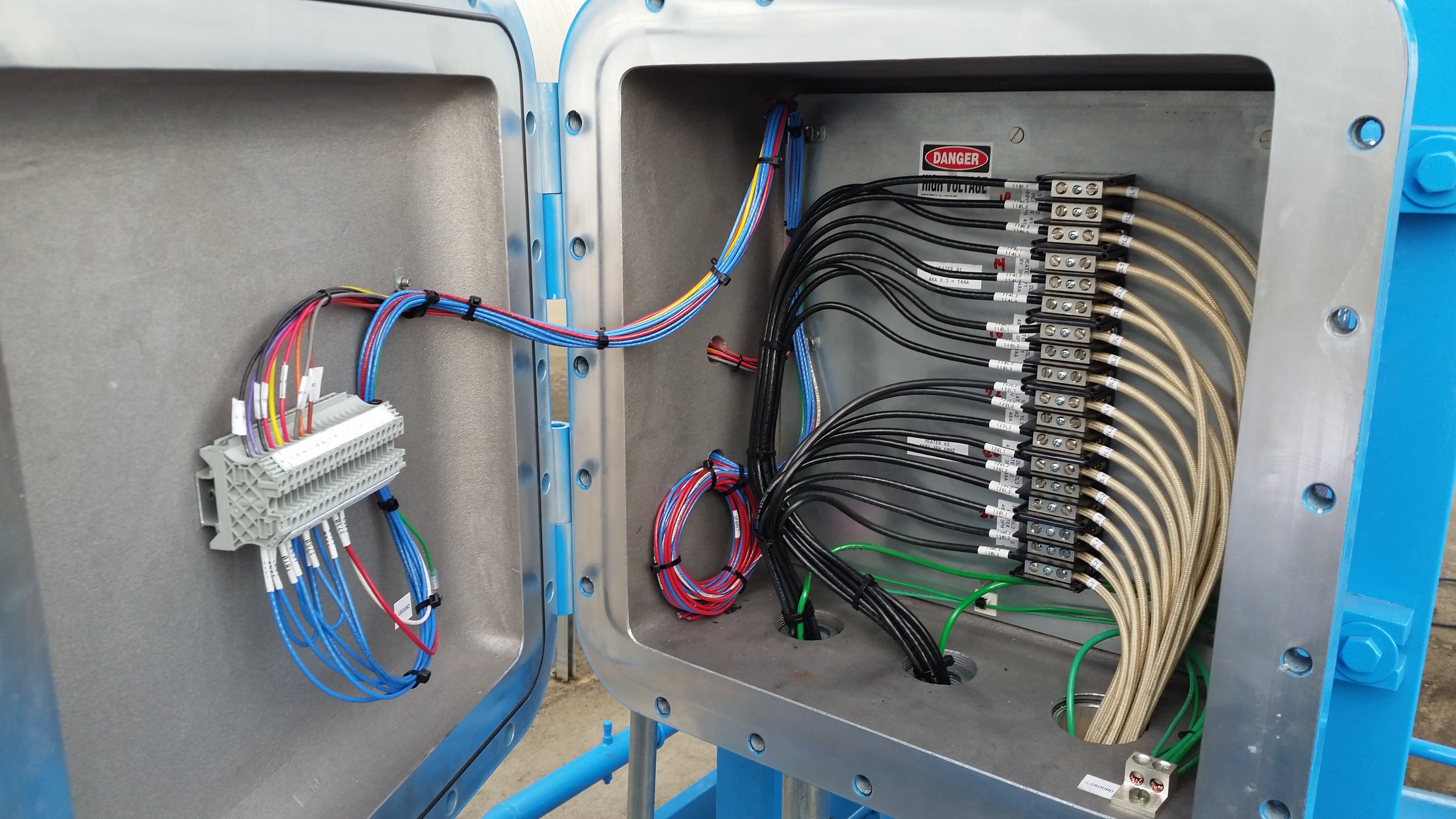

Lee Contracting has a full staff of industrial electricians who install and troubleshoot the electrical systems for our customers. Our electrical staff is complete with master electricians who can provide services ranging from routine plant maintenance all the way up to major electrical renovations. Our industry-leading modern equipment keeps our employees on the job instead of in the repair shop. Our key advantage is keeping a large electrical supply in-house for a quicker job turnaround and emergency service response.

Our highly-skilled staff of electricians are trained in:

- Installation of standby generators: backup lighting panels, UPS systems, and whole service backup power

- Emergency generator services: 24/7, 365 days a year

- Design and installation of primary power

- 24/7, 365 days a year emergency repair to get your shop back up and running, minimizing your downtime

- Control wiring specialist: from wiring upgrades to complete machine rewire

- Complete industrial installation: electrical design, motor controls and transformers

- Power quality monitoring: monitoring equipment to help determine and repair power quality issues.

- Infrared imaging: determine predictive maintenance

- Complete commercial and industrial lighting installation

Learn more about our electrical department by visiting our website.

Or call us today to request a free quote on your next industrial electrical project, 888.833.8776.

Subscribe and receive updates via email

According to the Bureau of Labor and Statistics, employment of electricians is projected to grow 9 percent from 2016 to 2026. Increases in construction spending and growing demand for alternative energy sources will drive demand for electricians. Many people choose to become an electrician because of the training, the pay and the benefits.

Apprenticeship Program

The path to becoming an electrician is through an apprenticeship program. After graduating high school or obtaining a GED, the apprenticeship program will have you working on actual job sites while learning the skills needed to become an electrician. Most times, the contractor your work for will pay for the apprenticeship program, eliminating thousands of dollars in student loan debt.

Great Pay

In the state of Michigan, the mean annual wage for electricians in 2016 was $56,600. Of course, this number can be increased with specialized training. After beginning your career as an electrician, promotions can include electrical engineer, cost estimator, electrical design engineer, and even master electrician. Master electricians can make $100,000 or more per year.

Working as an electrician is a great career choice. At Lee Industrial Contracting, we have a growing electrical department complete with master electricians who can provide services ranging from routine plant maintenance all the way up to major electrical renovations. We currently have several job openings in our Electrical Department. Check out our careers page, and apply today to join our growing electrical department.

Subscribe and receive updates via email

Skilled trades are a critical part of the nation’s workforce. The economy is improving and as baby boomers rapidly approach retirement, the need for tradespeople to replace them is continuing to increase. Many of these positions are in the industrial field. Here are four types of in-demand industrial careers and Lee Contracting’s open positions in the field.

- Electrician

Electricians install, repair, and maintain electrical wiring and equipment. Growth in the construction industry will mean more demand for electricians. At Lee Contracting, we currently are hiring: an electrical apprentice, master/journeyman electricians, journeyman electricians and an electrical estimator.

- Carpenter

Carpenters can be involved in many different aspects of construction. They can do anything from framing walls and setting concrete forms to building bridges and installing cabinets. Growth in the industrial field will boost the demand for carpenters over the next few years. Lee Contracting is currently looking to hire a building department estimator.

- Industrial machinery mechanic

This career is expected to have much faster-than-average job growth between 2016 and 2026—as machinery gets increasingly sophisticated, more mechanics will be needed to keep the equipment in good working order. Lee Contracting is currently hiring the following positions for their maintenance and repair department: machinist, industrial maintenance technician, machine repair journeyman, industrial maintenance technician-hydraulics and a field machinist.

- Heavy truck driver

Most of the freight in the U.S. is transported by truck. Heavy truck drivers are needed to move goods from one place to another. Lee Contracting is hiring a CDL-A driver with 2 years of experience and a clean driving record.

Subscribe and receive updates via email

Lee Contracting’s electrical department has been around since the beginning. Lee Contracting originally started in 1989 as Lee Electric in Clarkston, MI. Just 6 years later, Lee Electric became Lee Contracting and moved to Pontiac, MI. Our electrical department today continues to offer the best electricians and service in the industry.

Our electrical staff is complete with master electricians who can provide services ranging from routine plant maintenance all the way up to major electrical renovations. They use industry-leading modern equipment which helps to keep our employees on the job instead of in the repair shop. Our key advantage is keeping a large electrical supply in-house for a quicker job turnaround and emergency service response.

All our electricians are continually educated to stay current with code changes and new installation techniques. We train our apprentices through the Michigan State University apprenticeship program. This program allows our apprentices to gain on the job training and work experience while learning the theoretical and technical knowledge needed to become a successful journeyperson.

Lee’s highly skilled electrical department provides our customers with a wide range of capabilities including:

- Installment standby generators: backup lighting panels, UPS systems, and whole service backup power.

- Emergency generator services: 24/7, 365 days a year.

- Design and installation of primary power.

- 24/7, 365 days a year emergency repair to get your shop back up and running, minimizing your downtime.

- Control wiring specialist: from wiring upgrades to complete machine rewire.

- Complete industrial installation: electrical design, motor controls and transformers.

- Power quality monitoring: monitoring equipment to help determine and repair power quality issues.

- Infrared imaging: determine predictive maintenance.

- Complete commercial and industrial lighting installation.

Call us today at 888.833.8776 to take advantage of our electrical department’s capabilities. Or you can request a free quote on your next electrical project here.

Subscribe and receive updates via email

Energy conservation isn’t something that should just be practiced in a residential setting. There are ways manufacturing facilities can conserve energy and lower their overall energy costs. The Manufacturing Innovation Blog shows us some ways you can save energy and reduce your facility costs:

- Complete an Energy Audit

During this audit, your systems and equipment will be inspected and evaluated. This helps you to determine where your facility is consuming energy and at what rate. Your HVAC, lighting, compressed air and production systems might be included in this audit.

System leaks can be a source of wasted energy. If a leak is discovered during the audit, sometimes the fix can be as simple as tightening fittings or replacing minor parts. These small repairs can save you energy, time and money in the long run.

- Upgrade your Equipment

Brian Lagas of the National Institute of Standards and Technology, reminds us this doesn’t just mean manufacturing equipment. This can include ceiling fans, computer monitors, and other small electronics. Just like your major equipment on the shop floor, these small machines can become inefficient as they age. Replacing this equipment may be more budget friendly than replacing your entire HVAC system or replacing an outdated stamping press.

- Install Energy-Efficient Lighting

Having a well-lit manufacturing facility is important and the type of lighting used can help conserve energy. Using industrial compact fluorescent light bulbs (CFLs) or light-emitting diodes (LEDs) help to reduce energy usage. Another way to conserve energy is to install automatic switches to turn the lights off after no movement has been detected for a certain amount of time.

Using industrial compact fluorescent light bulbs (CFLs) or light-emitting diodes (LEDs) help to reduce energy usage. Another way to conserve energy is to install automatic switches to turn the lights off after no movement has been detected for a certain amount of time.

These are just three suggestions on how to conserve energy and reduce costs at your facility. While these changes may seem small, they can have a big impact in the long run.

If you are looking to do a facility lighting upgrade, call Lee Contracting at 888.833.8776 or you can request a free quote here.