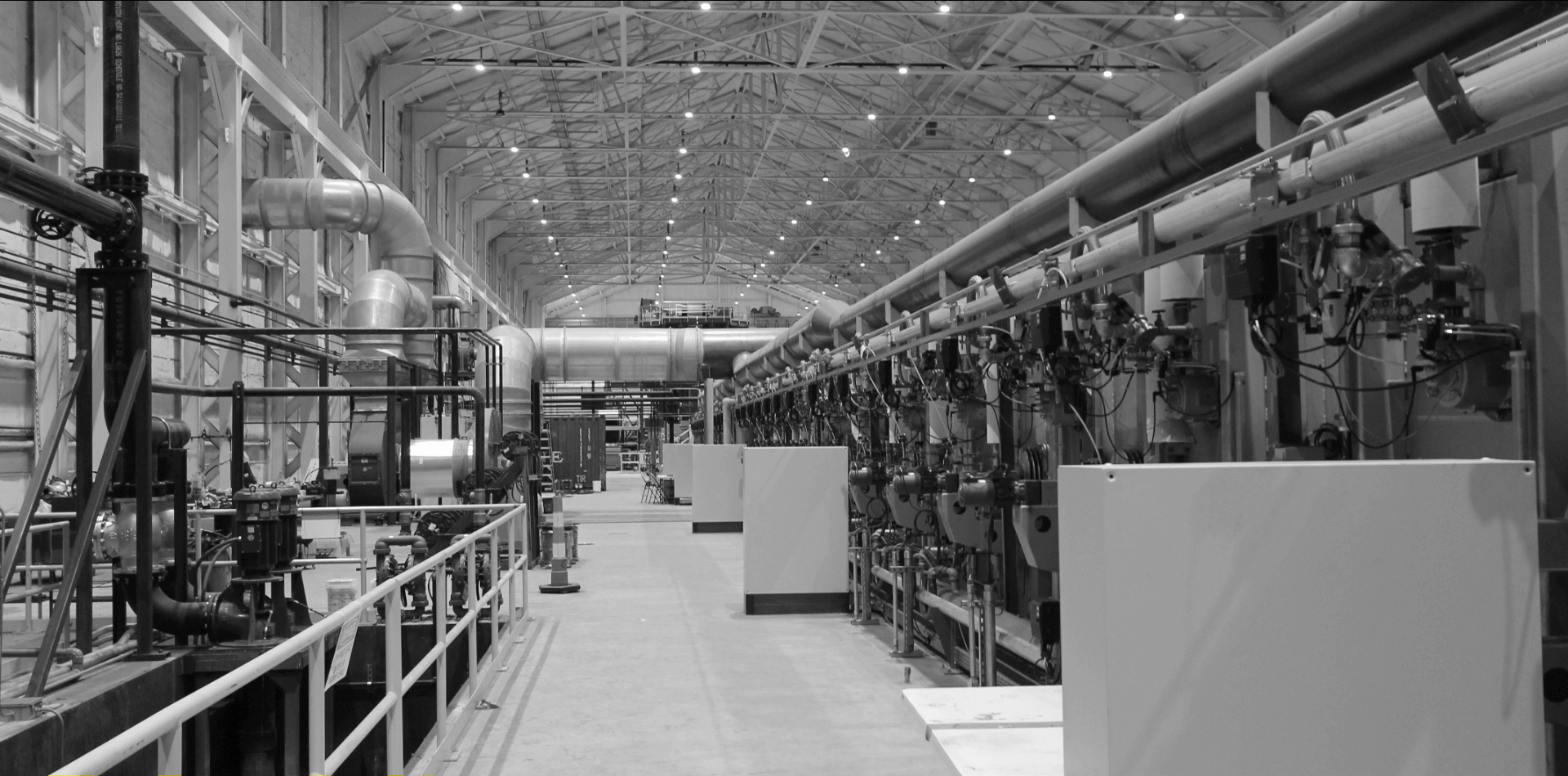

Experience Where Conditions Are Demanding

Lee supports heavy industry projects where scale, complexity, and risk are inherent to the work, including:

-

Steel and metals manufacturing

-

Cement, aggregates, and bulk materials processing

-

Power-intensive and high-temperature operations

-

Large rotating equipment and material handling systems

Our teams understand the realities of live plants, confined access, extreme loads, and shutdown-driven schedules — and plan accordingly.

Heavy Industry Capabilities

Lee delivers heavy industrial projects that often require multiple disciplines working in lockstep, including:

-

Equipment installation, removal, and relocation

-

Heavy rigging and specialty lifting

-

Foundations and structural concrete

-

Mechanical and piping systems

-

Electrical distribution and power support

-

Fabrication and structural modifications

-

Shutdowns, outages, and turnaround support

Whether work is executed by Lee crews, specialty partners, or a blended team, Lee leads coordination, sequencing, and safety — reducing handoffs and execution risk.

Designed for Live Facilities and Tight Windows

Heavy industry projects rarely happen in ideal conditions. Lee’s approach is built around:

Safety-Driven Planning

Hazard analysis, lift planning, and work sequencing are integrated early to protect people, equipment, and operations.

Shutdown & Outage Execution

We support planned outages and short execution windows with disciplined scheduling and trade coordination to maximize productivity and minimize downtime.

Integrated Coordination

Multiple trades, vendors, and specialty providers are aligned under one execution plan — reducing conflicts and keeping work moving.

Adaptability in the Field

Conditions change. Our teams are prepared to adjust sequencing and scope without losing control of safety, schedule, or cost.

Why Heavy Industrial Operators Choose Lee

-

One accountable partner leading execution from planning through completion

-

Experience in demanding environments where safety and precision matter

-

Flexible delivery model that applies in-house capability and specialty partners as needed

-

Proven ability to work in active facilities without disrupting operations

Our repeat relationships across heavy industry reflect trust built through consistent performance — not one-off projects.

Let’s Talk About Your Facility Challenges

If you’re planning equipment upgrades, structural modifications, outage work, or long-term capital improvements, Lee can help define the right execution approach — and deliver it with clarity and control.

LET IT SNOW

New foundations for a coil steel slitting line in the middle of an Indiana winter? With Lee’s in-house resources, this challenging job became a turn-key operation.

LEE INSIGHTS

TURNKEY OR JUST TALK?: How to spot the difference in industrial contracting.

“Turnkey” sounds simple: one provider, one contract, one smooth project. In industrial reality, the term is used so loosely that it can hide a lot of risk. A contractor can say turnkey, yet the customer still ends up coordinating multiple crews, managing…

From Reactive to Strategic: Building a 2026 Industrial Maintenance Roadmap

In 2026, successful manufacturers aren’t just maintaining equipment — they’re engineering reliability. This roadmap explores how facilities can evolve from reactive repairs to predictive and preventive maintenance strategies that drive uptime, safety,…

2026 Industrial Contracting Outlook: What Plant Leaders Need to Plan For Now

As U.S. manufacturing momentum accelerates into 2026, industrial leaders face growing pressure to plan strategically around reshoring, automation, and facility expansion. The most resilient organizations are partnering with turnkey industrial contracting…