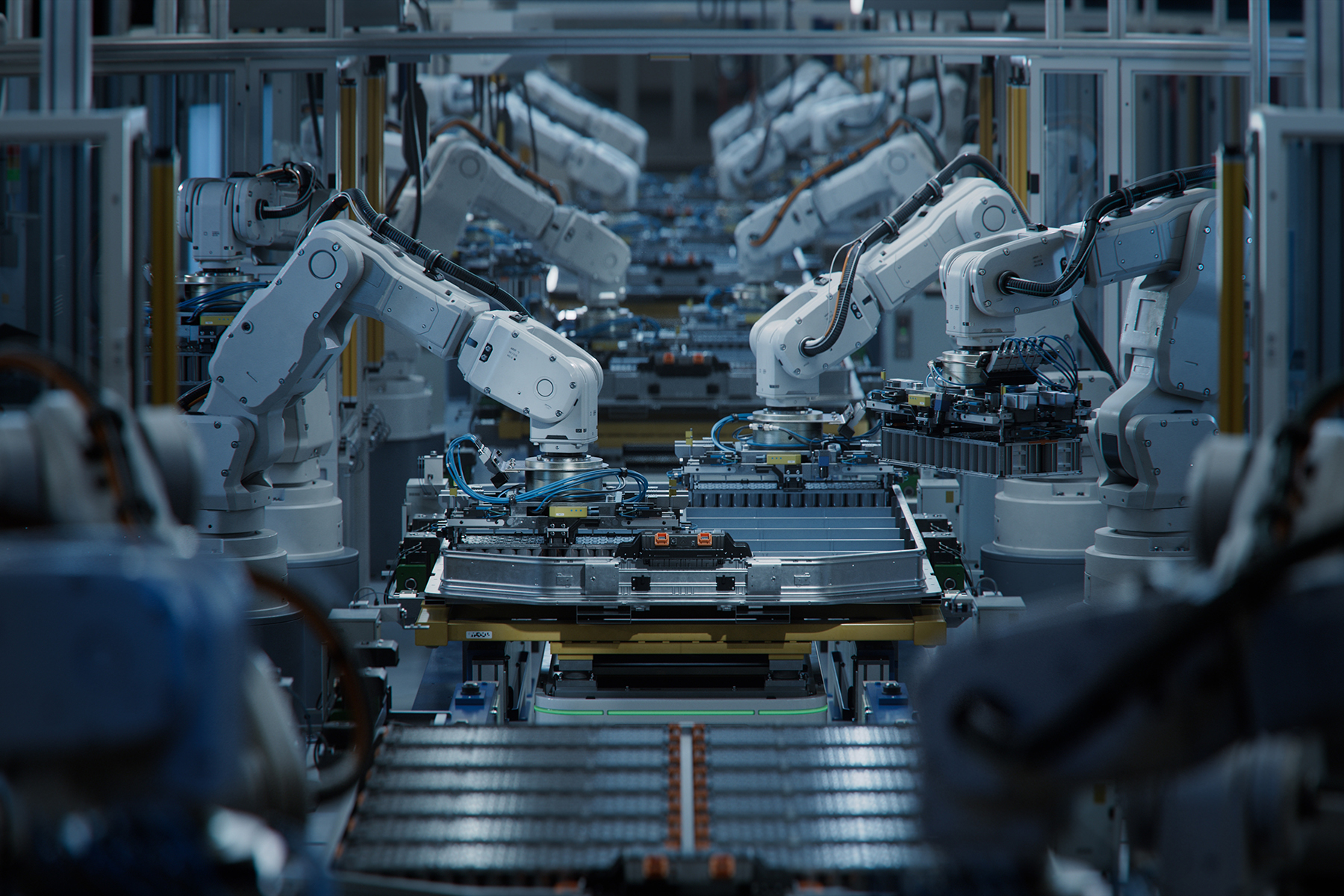

If you walk into a typical manufacturing plant today, you’ll likely come across equipment control systems that are a mix of old and new. Many facilities are still using legacy PLCs and other hardware that was installed decades ago. These systems might be working just fine, but they weren’t designed to communicate with the modern automation tools we see today.

The challenge? Upgrading without bringing your entire plant to a standstill.

The good news is, you don’t have to rip and replace all your legacy systems. At Lee Industrial Contracting, we’ve helped numerous facilities upgrade to automation solutions that integrate seamlessly with legacy equipment.

The key is to approach the project using thorough planning, analysis and a phased approach. Here’s how an experienced industrial contracting company like Lee Contracting helps manufacturers transition smoothly.

Step 1: Define Goals and Priorities

Installing modern equipment shouldn’t just be about having the latest and greatest. You first must ask, “Does this make sense for my business needs?” Here are some questions to consider before modernizing:

• Will modernizing help us meet our goals more efficiently?

• Do we need better access to data or real-time monitoring?

• Will automation help improve safety or compliance?

• Is it cost-effective?

Understanding your goals helps you identify what should be upgraded first so we can build a phased roadmap rather than trying to tackle everything at once.

Step 2: Assess Your Current Systems

Before any plans are made, we first must understand what you’re working with now. An experienced industrial contracting controls team will evaluate everything from the age and condition of your PLCs and HMIs to software compatibility to network infrastructure.

Once the evaluation is complete, we’ll have a better picture of what the project will need. We’ll consider which components can be retained, which will need upgrading and what challenges we might encounter during implementation. We’ll also identify any potential safety issues so we can create plans to avoid them.

Step 3: Design a Phased Integration Plan

Some teams get overly ambitious and think they can perform a complete controls overhaul within a short shutdown window. This is a mistake. Trying to rush the project leaves no time for unexpected issues, thorough testing or proper training – all things that can increase the risk of added downtime.

At Lee Industrial Contracting, we approach modernization with a step-by-step integration plan. This might include:

• Running new wiring and panels in parallel to existing systems

• Upgrading PLCs and software in stages

• Testing new components offline before switching over

• Scheduling cutovers during planned maintenance window

This step-by-step approach breaks up work into manageable phases, allows time to find and fix problems early and enables you to train staff gradually. This way, you avoid surprises and keep your systems running.

Step 4: Execute with Cross-Functional Expertise

Controls integration isn’t just a job for an engineer. Many trades must be brought in to ensure all systems work properly. Electricians, programmers, mechanical specialists and engineers work together and communicate constantly on the project.

This is where working with the team at Lee Industrial Contracting gives you an advantage. Since we have all these trades in-house, we can streamline scheduling and make sure all teams are aligned.

As a self-performing industrial contractor, we can build and install electrical panels, program PLCs and HMIs to interface with legacy equipment and perform testing and validation before go-live.

When all trades are coordinated under one roof, you avoid delays and finger-pointing between multiple industrial contractors.

Step 5: Train and Support Your Team

Even the best technology can fail without proper training. Hands-on training must be conducted to ensure operators and maintenance teams understand the adjustments to their work. This empowers your staff to run and troubleshoot the new controls confidently.

Ongoing support such as remote diagnostics and updates help to keep your operations running smoothly after the upgrade.

The Right Path to Modernization

Integrating automation into your legacy production lines is a smart decision. Partnering with an experienced, self-performing industrial contracting partner helps you bridge the gap between legacy systems and modern automation equipment smoothly. Whether you’re upgrading a single press line or an entire facility, a phased approach reduces risk while you build a smarter, more efficient facility.