3D modeling has changed the way design and planning is done in a variety of industries. It provides a perspective and level of detail that 2D modeling just can’t do.

Lee Contracting utilizes 3D modeling to better help our clients visualize their project. How do we do that? Find out below.

What is 3D modeling and how is it used for foundations?

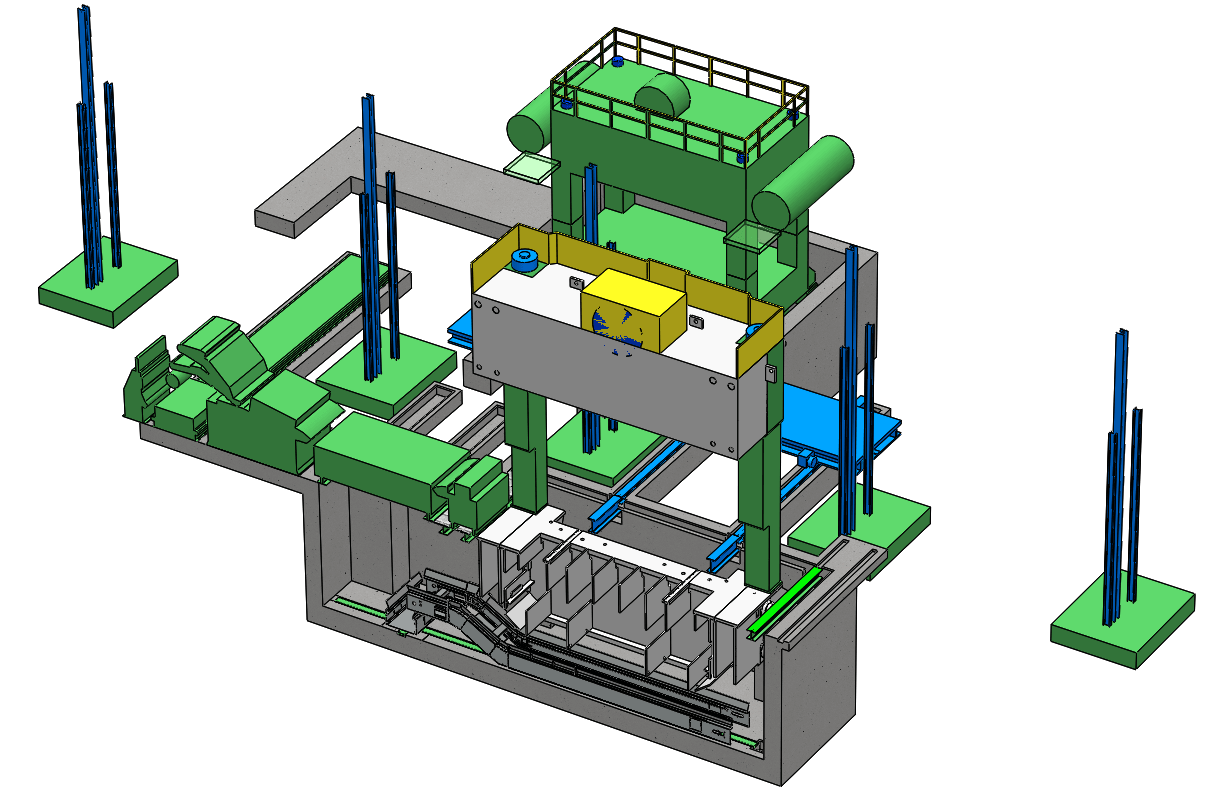

At Lee Contracting, our engineers use SolidWorks, a CAD-based program, to create digital 3D models of before our team even steps foot on the job site.

The process begins when our experienced team receives a general assembly drawing from one of our clients. Next, our skilled engineers create the client’s vision in 3D by integrating their new plan, and their secondary equipment, into one overall design. This helps ensure all the equipment and machinery will work together properly (i.e., mapping trench measurements and routing in the foundations to support all secondary equipment).

Our engineers color code the model to indicate a change in materials, departments, machinery, etc. After the model is finished, a PDF version of the proposed plan is exported and presented to our client.

What are the benefits?

There are several advantages to engineering a 3D project model prior to beginning large, design-build foundations jobs.

- Saves Time: By creating a 3D project model, any potential issues/challenges can be caught before even breaking ground. This allows Lee’s team to go into the project with an efficient plan which has an extremely low probability of error. This saves our teams from having to problem solve on the spot and/or reverse any work that has already been done.

- Saves Money: Since 3D project models help to eliminate errors, this lowers costs as materials and working time are not wasted due to errors.

- Allows for more accurate quoting: 3D modeling helps our estimators accurately quote the project. The model outlines the exact materials and work needed for the job.

- Easy viewing for clients: The 3D model can be exported from SolidWorks to a PDF, so anyone with Adobe Acrobat Reader can have a 360-degree view on the model.

What are the challenges?

While 3D modeling for foundations projects has many benefits, our engineers are faced with challenges along the way. Many clients have a proposed budget already in place for their project, and it’s up to our engineers to design a plan that fits within the client’s budget. Depending on the works that needs to be done, our engineers do their best to find the most cost-effective solution to meet our client’s needs.

3D project modeling is a service not many other industrial contractors offer; however, the process has been perfected by the engineers at Lee. Request a quote today to get your 3D plan started: https://www.leecontracting.com/request-a-quote/