Two weeks ago, we discussed the importance of preventive maintenance. Preventive Maintenance is also extremely necessary for electrical equipment. A great deal can go wrong if an electrical system is not adequately maintained. As electrical loads cycle between high and low demand, thermal expansion and contraction cause connections to loosen. Electrical panels that are never cleaned accumulate dust and dirt that deposit on these connections. The loose and dirty connections provide a high resistance path that are directly responsible for more than 30 percent of electrical failures. Another 17 percent of electrical failures are attributed to live electrical components being exposed to moisture. With a comprehensive electrical preventive maintenance program, both conditions — which account for almost half of all electrical losses — can be corrected.

*Thermal Imaging maintenance should be completed on electrical equipment every 12 months.

How Preventive Maintenance Saves You Money

- Reduced Downtime

- Increase Operational Efficiency

- Reduce the Risk of Expensive Reactive Maintenance

- Increase the Life of Equipment

- Improved Customer Service

With the failure rate of electrical equipment being 3 times higher for components that are not included in a scheduled preventive maintenance program, the benefits are hard to argue. We can plan maintenance in coordination with scheduled shutdowns to reduce downtime. Our electrical team is continuously trained and keep up to date on electrical codes and regulations.

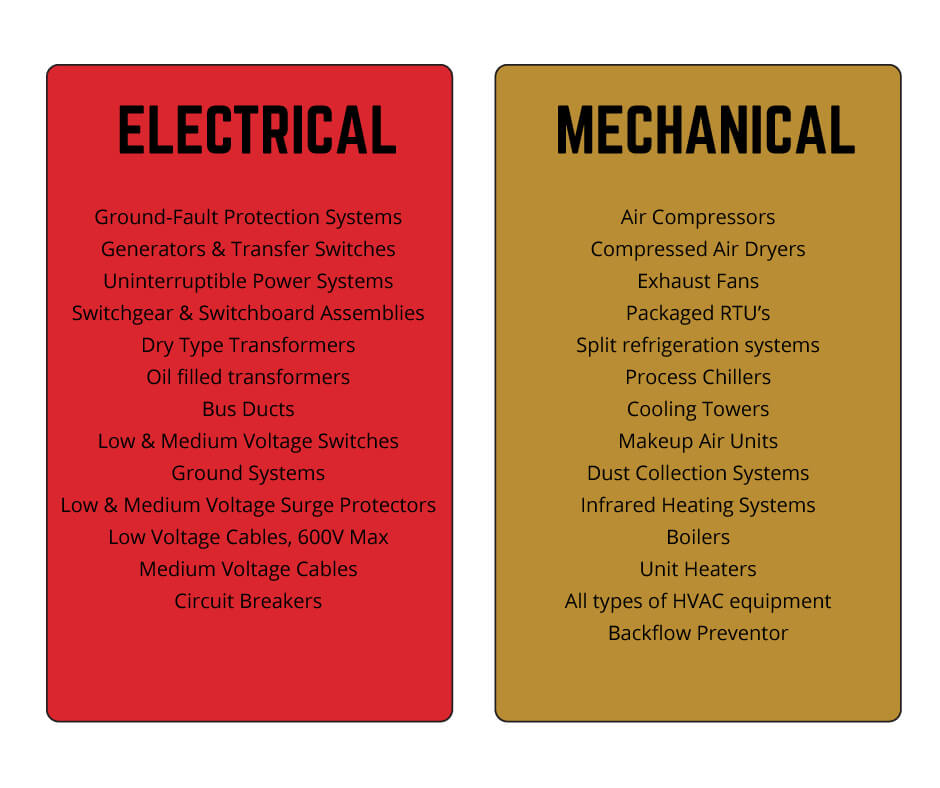

We pride ourselves on removing the barriers that come with hiring multiple contractors. With all our trades under one roof, we control every aspect of your next project, saving you time and money.

Interested in implementing an effective preventive maintenance plan for your business or organization? We can help determine your maintenance plan and what your equipment needs.

Contact us today or call us at (888) 833-8776 to learn how we can manage your production with preventive maintenance.