Any industrial facility relies on piping to perform crucial tasks and functions. Accordingly, securing reliable industrial process piping service is key, whether you need a new installation or require maintenance and repair of an existing system. With experience that spans for three decades, we stand out as a leader in industrial pipefitting. We offer a wide range of knowledge and capabilities, which allows us to tackle many diverse projects. The following are a few key traits that set Lee Contracting apart from the competition.

Different Piping Materials

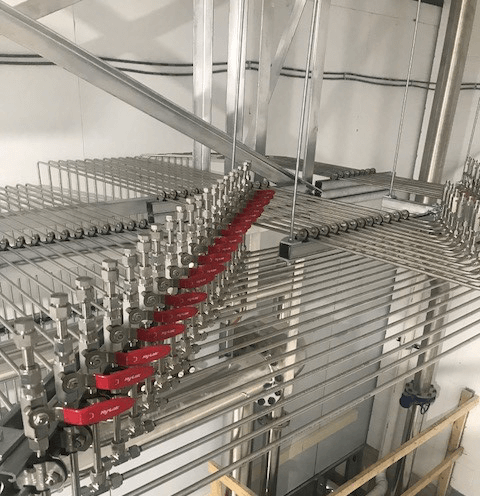

The types of pipefitting materials your plant needs typically depends on the kind of work performed. For example, highly corrosive environments require stainless steel piping, since this material can withstand corrosive elements. Conversely, plastic piping systems often have applications in chemical processing and water treatment. We specialize in many types of materials to best serve your needs, including:

- Carbon Steel

- Stainless Steel

- CPVC

- PVC

- Galvanized

- Copper Aluminum

- Ductile Iron

Inventory

An integral part of our mechanical department is our fully stocked inventory of all piping and tubing materials. This advantage allows for quicker job turnaround and emergency service response for all your pipefitting needs.

Certifications

Our pipefitters are highly skilled and dedicated to providing the best piping solutions. The qualifications and certifications that we hold include:

- Certified Victaulic installers

- ASME B31.3 PVC and CPVC bonder qualification

- ANSI/ASME B31 qualified welders for carbon steel and stainless steel pipe

Capabilities

When we combine our materials, certifications, inventory and experienced staff, our capabilities become endless. Below are some of the possibilities that our pipefitting department provides:

- Quality design, installation and repair of all types of piping systems including complete cooling systems.

- Process piping installations, including but not limited to the following: gas, hydraulic, compressed air, cooling water, refrigeration, coolant, steam and condensate, fuel, lube, material handling and vacuum.

- Joint methods include the following: grooved, welded, brazed, soldered, threaded, flared, glued, mechanical pressfit (propress), cone and thread and compression.

- Complete rough and finish plumbing installations including water service piping, backflow installation, backflow certification and service.

- Pipe insulation installation.

- Chiller and pump skid rental and installation available.

- 24/7, 365 days a year emergency service.

We bring all the above traits to every project, no matter the size or scope of the task. If you’d like to get started on a quote for an upcoming project, please visit our website.

You can also call (888) 833-8776 to receive your free quote today.