Tag: Equipment Maintenance

Repairing your press is extremely important to keep production at maximum efficiency. Taking the time to inspect your press can save you time and money in the future. When your press is being dismantled for repair, this provides a great opportunity to inspect the press for any further repairs or modifications to enhance the system. Taking this time to inspect the press can save time and money. A large part of the expense of equipment repairs or modifications is the labor associated with teardown and inspection.

Timing your press repair around a relocation is beneficial because production downtime is already planned. Components targeted for replacement or repair can be dealt with while the rest of the machinery is being moved to its new location. In many cases, components can be repaired and reinstalled with the other equipment as a seamless process.

For example, during the dismantle inspection, it may be revealed that the drive shaft or the ram needs to be rebuilt. Discovering any issues at this point and having all repairs and upgrades completed during this already scheduled downtime will save time and money in the long run. If the components are not rebuilt during this time, they will need to be fixed in the future which could cause disruption to production schedules. This would also be costly due to having to dismantle the press twice to reach and rebuild the components.

For example, during the dismantle inspection, it may be revealed that the drive shaft or the ram needs to be rebuilt. Discovering any issues at this point and having all repairs and upgrades completed during this already scheduled downtime will save time and money in the long run. If the components are not rebuilt during this time, they will need to be fixed in the future which could cause disruption to production schedules. This would also be costly due to having to dismantle the press twice to reach and rebuild the components.

Lee Contracting has its own in-house maintenance and repair department. Our highly-skilled machine repair, industrial maintenance and machinist teams can maintain, troubleshoot, repair and rebuild your machinery. We offer on-site machine repair, or we can take your equipment to our fully equipped facility to perform repairs.

Our machining team uses state-of-the-art precision manufacturing equipment for reliable accuracy and consistency. We also offer portable machining services that enable us to keep your downtime to a minimum as well as save thousands of dollars by not having to completely disassemble large machinery.

Call us today at (888) 833-8776 for a free quote on relocating or repairing a press, or click here.

Subscribe and receive updates via email

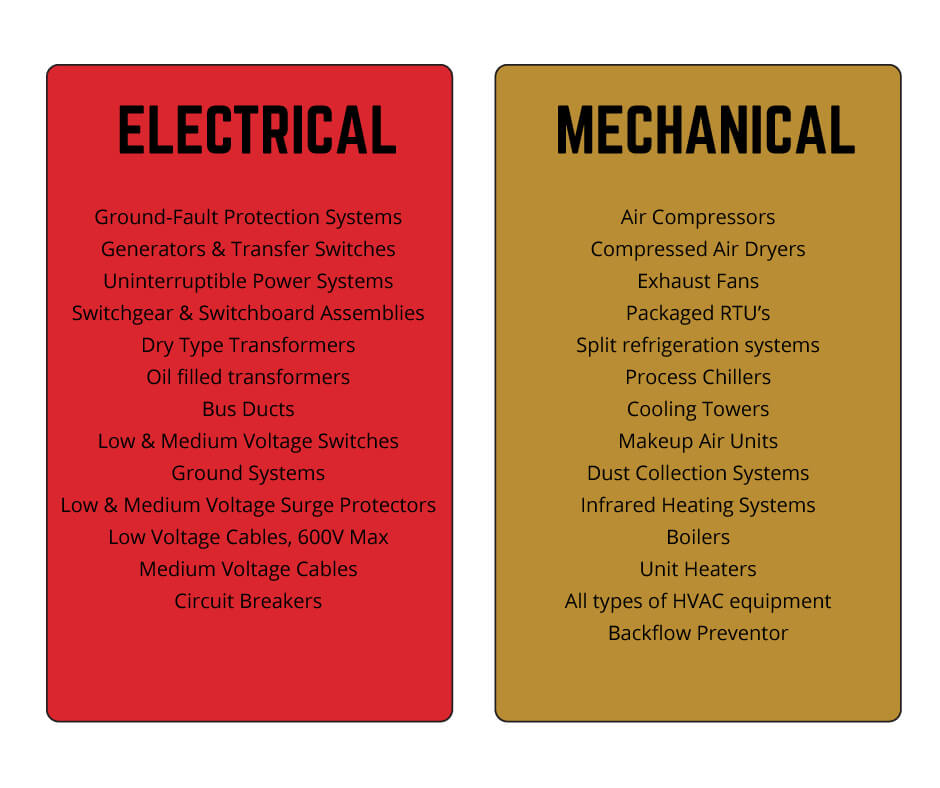

Two weeks ago, we discussed the importance of preventive maintenance. Preventive Maintenance is also extremely necessary for electrical equipment. A great deal can go wrong if an electrical system is not adequately maintained. As electrical loads cycle between high and low demand, thermal expansion and contraction cause connections to loosen. Electrical panels that are never cleaned accumulate dust and dirt that deposit on these connections. The loose and dirty connections provide a high resistance path that are directly responsible for more than 30 percent of electrical failures. Another 17 percent of electrical failures are attributed to live electrical components being exposed to moisture. With a comprehensive electrical preventive maintenance program, both conditions — which account for almost half of all electrical losses — can be corrected.

*Thermal Imaging maintenance should be completed on electrical equipment every 12 months.

How Preventive Maintenance Saves You Money

- Reduced Downtime

- Increase Operational Efficiency

- Reduce the Risk of Expensive Reactive Maintenance

- Increase the Life of Equipment

- Improved Customer Service

With the failure rate of electrical equipment being 3 times higher for components that are not included in a scheduled preventive maintenance program, the benefits are hard to argue. We can plan maintenance in coordination with scheduled shutdowns to reduce downtime. Our electrical team is continuously trained and keep up to date on electrical codes and regulations.

We pride ourselves on removing the barriers that come with hiring multiple contractors. With all our trades under one roof, we control every aspect of your next project, saving you time and money.

Interested in implementing an effective preventive maintenance plan for your business or organization? We can help determine your maintenance plan and what your equipment needs.

Contact us today or call us at (888) 833-8776 to learn how we can manage your production with preventive maintenance.

Subscribe and receive updates via email

Our turn-key services get your job done from start to finish. Our specialized equipment sets us apart from the competition. Owning our equipment allows us to provide the best competitive rates to lower project costs. Our specialized equipment allows us to perform all different types of projects.

A short list of our in-house equipment consists of:

- Fork Trucks

- Man Lifts

- Gantry Systems

- Excavation Equipment

- Cranes

- Die Carts

- Generators

Goldhofer

Our Goldhofer is a unique piece of equipment that not many industrial contractors own. The Goldhofer is a self-propelled modular transporter with 10-axles and a 1-million ton capacity. This specialized piece of equipment can travel down roads and make the impossible, possible.

Our Goldhofer is a unique piece of equipment that not many industrial contractors own. The Goldhofer is a self-propelled modular transporter with 10-axles and a 1-million ton capacity. This specialized piece of equipment can travel down roads and make the impossible, possible.

Maintenance & Repair

Our team of dedicated mechanics provide the best service and maintenance work in the industry. This means that if your current equipment needs to be serviced, we are here to help get your equipment back in working condition. Our maintenance and repair department teamed together with our specialized equipment provides versatile protection of your current equipment with the ability to help you expand your production.

Want to learn more about what we can do with our in-house equipment?

Call us today for a free quote on your next project at (888) 833-8776 or request a quote online.

Subscribe and receive updates via email

Regular maintenance of equipment is an important and necessary activity. Maintenance covers many activities including inspection, testing, measurement, replacement and adjustment. There are two types of maintenance: preventive maintenance is planned and focuses on preventing future problems, while corrective maintenance is reactive and occurs when equipment requires service to be repaired. Preventive maintenance is all-inclusive to improve reliability, reduce the probability of an unexpected breakdown and extend your equipment’s lifespan.

Our equipment maintenance teams are highly trained and skilled to know the ins and outs of your equipment. Our knowledgeable staff is productive and safe, which means your equipment is in the best hands.

Maintenance can be a high-risk activity. There can also be difficulties in accessing equipment that requires maintenance and this may require work at heights or confined space entry. At Lee Contracting we always ensure that safe working procedures are followed. Our technicians prepare their workspace, complete any necessary safety documents, identify potential hazards, make sure to be equipped with the correct tools and wear PPE. Our safety department helps eliminate safety hazards. We continue to maintain safe, organized, clean and efficient job sites as the safety of our personnel and customers is always our top priority.

Maintenance can be a high-risk activity. There can also be difficulties in accessing equipment that requires maintenance and this may require work at heights or confined space entry. At Lee Contracting we always ensure that safe working procedures are followed. Our technicians prepare their workspace, complete any necessary safety documents, identify potential hazards, make sure to be equipped with the correct tools and wear PPE. Our safety department helps eliminate safety hazards. We continue to maintain safe, organized, clean and efficient job sites as the safety of our personnel and customers is always our top priority.

Our approach is to provide preventative maintenance for your machinery & equipment. But we know that emergencies happen, which is why we provide 365-day, 24/7 emergency service to those in need of getting equipment up and running. Our machine repair department is made of highly skilled machine repair, industrial maintenance and machinist teams ready to maintain and repair your equipment.

Call us today to receive a free quote for your next industrial project, (888) 833-8776.