Planning a fabrication project is no small undertaking and requires a lot of planning and forethought. As you begin this process, you must consider things like budget, schedule, design and implementation. There are numerous steps along the way, and while some may seem small, if they’re not completed, might cause delays. If you’re ready to begin a new project, find out how Lee Industrial Contracting can provide excellent industrial fabrication services to ensure your success.

To help you understand what we offer in our services, here are the main phases of an industrial fabrication project, and why each of them is critical to the process.

Engineering Design

As you start your project, you’ll be working with our in-house engineers. The first step is to communicate what your end goal is; what final product you are looking for. Your project could be for a new set of stairs in your lab facility, a mezzanine designed and installed in your warehouse, or a structural steel layout for your shipyard. Whatever you require, our designers will deliver a high-quality design.

While the final goal is important, we also need to know if there are any constraints on the project. We will need to know of any legal statutes, regulatory compliance, spec requirements or load limits tied to your final product. All of these are important pieces of information that our engineers will need to keep your project in compliance. All designs are checked by structural engineers to ensure soundness.

The design phase is the most important part of your project. Our engineers will work closely with you to ensure the design is right the first time and that you are satisfied with the result.

Manufacture and Build

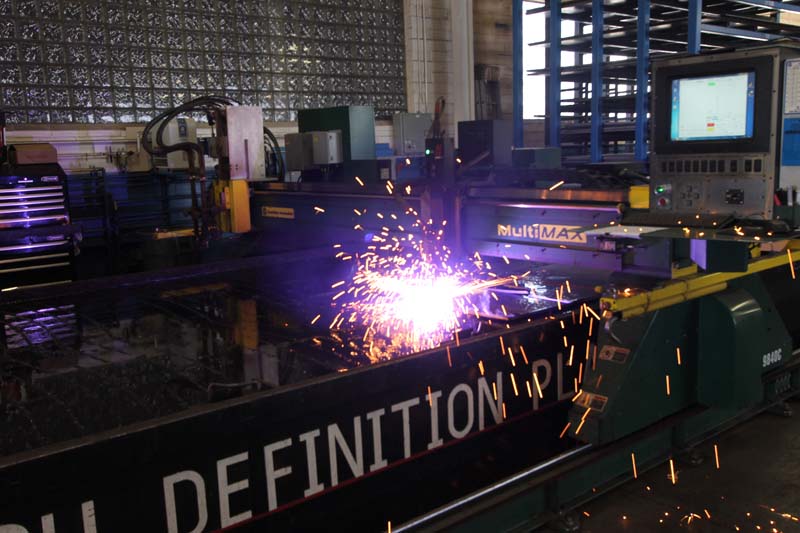

After the design is complete, it’s handed off to our manufacturing and building team. This professional group will be responsible for cutting metal to specifications using our HyDefinition Plasma Machine and OMAX waterjet cutting machine.

Once the metal is cut to spec, it will be manipulated – if needed – into the desired shape. This step often involves using one of our presses, employing our Baileigh tube bender and using other specialized equipment.

Next, we begin the build process. This may either be a complete build for smaller projects or a partial build for larger projects that need final assembly on-site. Using our fully equipped welding rigs, with AWS D1.1 certified welders, we carefully assemble the product to match the specifications of the design team.

Every step of the manufacture and build process is inspected to ensure it meets welding codes and conforms to the design.

Treatment and Assembly

Corrosion treatment and final assembly will depend on the size of the project, as noted above. For small projects, we will fully assemble the product, then apply our corrosion protection treatment and final paint. This is all done in-house, before transportation.

For larger projects, final assembly won’t occur until individual pieces are transported to the install site. Once onsite, we will do final assembly, including all necessary welding. After an inspection for design conformance and welding codes, we will apply corrosion treatment and paint.

When you work with our industrial contracting company, you receive first class customer service from the design phase until final assembly.

Contact Lee Industrial Contracting Today

You won’t find a company that is more dedicated to providing you a high-quality product and a great experience than Lee Industrial Contracting. If you’re ready to begin your industrial fabrication project, or if you have any questions about the process, we’re ready to answer. Please reach out to us today through our web form, or give us a call at (888) 833-8776. Our qualified team of engineers and professionals is ready to answer your questions and start you on the road to a successful project.