Tag: industrial foundation

The foundation is the base for your facility and your equipment. Creating a solid groundwork for your equipment is determined by different factors. Keep reading for a breakdown about some different foundation components.

Footing: The footing is the part of the foundation that supports the concrete slab, floor joists, or blocks. Footings are formed by filling an excavated ditch with concrete to ground level. The footing runs along the entire perimeter of the structure.

Stem Wall: A stem wall is a short reinforced concrete wall rising above the ground and running the perimeter of the structure. They can be poured at the same time as the slab or the footing. Stem walls protect a structure by raising its elevation and guarding against flooding.

Pier: Piers are excavated holes filled with reinforced concrete running at intervals along the perimeter of a structure. Footings and stem walls often have piers.

Grade Beam: Grade beam is a reinforced concrete beam that diffuses the load from a bearing wall into spaced foundations.

With the different components that go into installing your flawless foundation, trusting the right contractor is an integral part of the selection process. Our expert foundation installation team is highly skilled and capable of completing nearly any type of concrete work. With our proprietary excavation technique, in-house staff and state-of-the-art equipment we are ready to install the right foundation for your job.

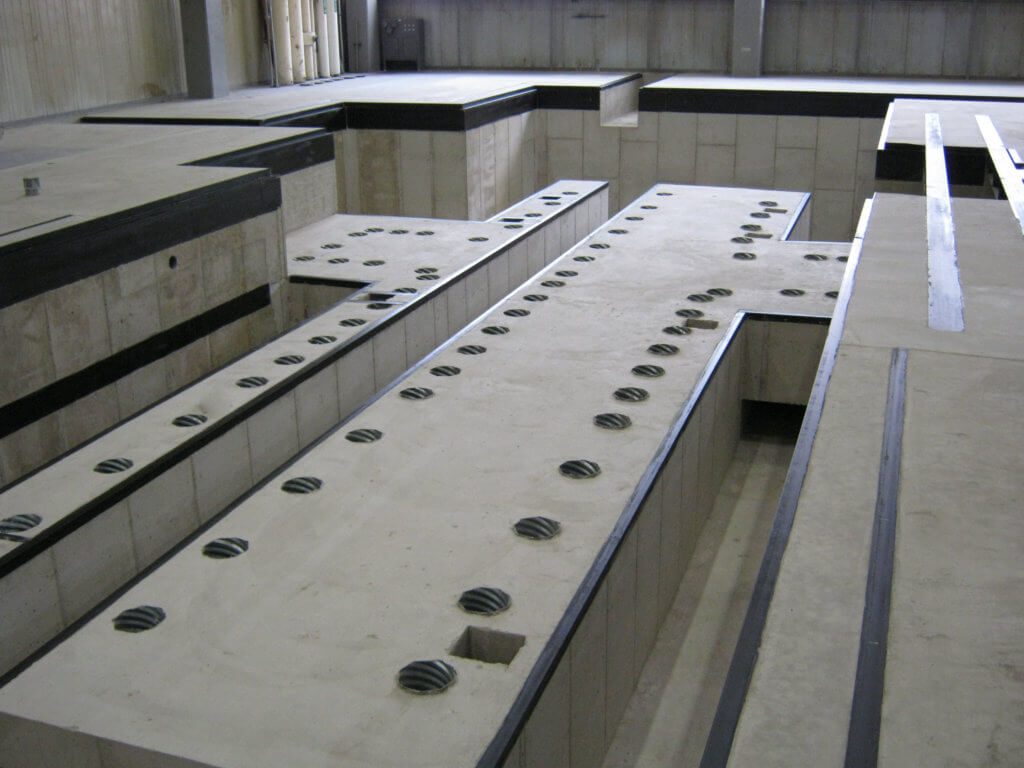

We specialize in installing:

- Stamping press foundation pits

- Injection mold machine foundations

- Slitter/cut to length foundations

- Mill foundations

- Precision grouting

- Isolation pads

- Floor slab replacement

- Site concrete

- Poured walls

We pair the best materials and equipment with the latest industry practices to provide world-class results. Our turn-key approach and in-house talent allow us total control of engineering, earth retention, resteel, form work and concrete placement. Learn more about our foundation installation capabilities today.

Call us today for a free quote on your next project at (888) 833-8776 or request a quote online.

Subscribe and receive updates via email

Pouring concrete in the winter can cause major problems in the quality and longevity of your new foundation. If newly poured concrete is not given the appropriate environment to cure, the concrete is likely to be damaged. This is due to the water in the concrete mix freezing and expanding, resulting in weak concrete. The American Concrete Institute defines cold weather as three or more consecutive days of low temperatures below 40 degrees Fahrenheit and air temperature below 50 degrees Fahrenheit for more than a 12-hour period.

When pouring concrete in cold weather, the concrete needs to be protected until it can handle the cold on its own. The general rule is that concrete must reach a strength of 500psi. At almost the same time that the concrete achieves 500psi strength, the cement has consumed enough of the water in the original mix so that even if it does freeze, there’s not enough water left in the pores to damage the concrete. With most concrete this happens 48 hours after the pour.

To help the concrete reach 500psi, there are two things we can do in cold weather: Change the mix to get it to set more quickly or protect the concrete from the cold—or more likely, both.

Mistakes to avoid when pouring concrete in cold weather:

- Not scheduling work around weather

- Pouring on frozen ground

- Allowing concrete to freeze

- Not using heaters

- Not using real-time temperature sensors

You must ensure that concrete is cured properly for safe removal of forms and shores and for safe loading of the structure during and after construction.

Our foundation experts work to ensure the highest quality on your project. Our experience guarantees a successful foundation for all your industrial projects.

Get started on a quote for an upcoming project by filling out our online form. You can also call (888) 833-8776 to speak with a representative today.

Subscribe and receive updates via email

When your factory or warehouse is in prime condition, the entire operation runs like clockwork. However, even a few minor inefficiencies can drastically reduce the overall effectiveness and profit of your company. The foundation of all your efficiency is your industrial concrete floor. If you have a damaged concrete slab, find out how Lee Industrial Contracting can offer effective industrial floor slab replacement services in record time.

Identifying the Issue

A few minor cracks in your flooring could be harmless, or they could require immediate attention and affect the overall integrity of your foundation. Our expert contractors are highly experienced with a variety of concrete applications. We can inspect your floor to ensure that any chip, crack or unsafe flooring is professionally replaced.

At times, it may be difficult to determine the extent of the damage to your concrete flooring. Without professional experience, a minor crack and a major structural fracture may look similar. Be sure to ask for a professional inspector to diagnose any issues in your concrete flooring to ensure the problem is caught and repaired before it’s too late.

Preventing Further Damage

Don’t wait until the problem is large enough to halt production. As an expert industrial contracting company, we can provide preventative services that can test and accurately assess the quality of your concrete slab flooring. Accurate checks allow issues to be resolved before they grow into major problems.

Repairing Your Concrete Slab

When a floor slab replacement service is needed, you’ll receive efficient services with the highest quality products. Our team specializes in the latest services that keep your floor smooth, structural and ready to support your business, including:

- Rebonding floor slabs

- Resealing joints

- Replacing slabs

The type of service that your flooring needs will depend dramatically on the size and scope of the damage. Minor sealant issues can be quickly fixed, while replacing entire concrete slabs can take longer. An experienced contractor can discuss the various options available to you and determine the best course of action for your company.

Choosing a contractor that understands the industrial world means you’ll find a crew of highly experienced contractors that can work around your schedule. Don’t let a few cracks in your floor cause your factory to lose precious hours of operation.

Complete Concrete Services

Our services extend beyond simple concrete slab repairs. At Lee Industrial Contracting, our team is capable of a diverse range of specialized industrial applications of concrete and other foundation materials. Whether you need to pour a new foundation and walls, replace your current slab floor or hire customized precision grouting, our team is ready to keep your industrial facility running efficiently.

While repair services are underway, this could be an excellent time to review any new additions you may be considering to your industrial space. Whether you need service pits, new walls or an expanded shop floor, our team is capable of it all.

Quickly Replacing Your Concrete Slab

When it comes to concrete repairs and replacement, time is money. Waiting for contractors who aren’t used to the pressures of industrial applications can cost you invaluable hours or even days. Choose a contractor who understands the industrial pace and is ready to provide prompt and effective services that get the repairs done right the first time.

Contact Lee Industrial Contracting Today

Few local contractors can match the speed, experience and premium quality of Lee Industrial Contracting. If you’re ready for an estimate on a floor slab replacement or have a few questions about a concrete project in your industrial building, contact us today. You’ll find the qualified team of professionals you need to keep your company running efficiently and staying profitable.