Category: Blog

Ductwork plays an important role in industrial facilities. Large HVAC systems maintain air quality, employee health, and quality assurance benchmarks. These large, secure passageways for airflow improve total system efficiency and reduce the likelihood of an air quality crisis. Any process that creates health hazards in an enclosed environment will benefit from a properly sized duct system.

Ductwork plays an important role in industrial facilities. Large HVAC systems maintain air quality, employee health, and quality assurance benchmarks. These large, secure passageways for airflow improve total system efficiency and reduce the likelihood of an air quality crisis. Any process that creates health hazards in an enclosed environment will benefit from a properly sized duct system.

Marc Neiman, Lee Contracting’s HVAC Coordinator warns that duct systems that are too large or too small can impede airflow levels, ventilation, and dust collection system performance. Industrial ductwork contains air flow passageways designed to keep pace with air volume requirements. These duct systems are important in areas that rely on consistent temperature management and efficient dust collection/ventilation.

Dust collection systems are integrated within an industrial HVAC system. These systems rely on ductwork to carry industrial dust from a machine to the collection system. Large ductwork can accommodate these industrial applications to deliver consistent air quality without overtaxing the system.

Industrial ductwork systems often feature galvanized, stainless, or rolled steel  constructions to deliver maximum performance in an industrial environment. Industrial environments need carefully designed, fabricated, and installed components to meet regulatory air quality standards and minimize system maintenance requirements. Sometimes, prefabricated ductwork systems may not meet the standards for a facility. When this occurs, the facility will benefit from a custom fabricated HVAC system design.

constructions to deliver maximum performance in an industrial environment. Industrial environments need carefully designed, fabricated, and installed components to meet regulatory air quality standards and minimize system maintenance requirements. Sometimes, prefabricated ductwork systems may not meet the standards for a facility. When this occurs, the facility will benefit from a custom fabricated HVAC system design.

Lee’s HVAC department is prepared to handle any project when it comes to your sheet metal fabrication, installation,  service, and preventative maintenance needs. Our key advantage is maintaining a fully stocked sheet metal and fabrication shop to meet our customer’s needs, whether it is on a moment’s notice or a large planned-out project. Our teams can handle any project of any size to get the job done. We have experience installing dust collection systems, exhaust and ventilation systems, roof top, split or ductless systems, chiller systems, refrigeration piping, environmental chambers and computer/server room systems.

service, and preventative maintenance needs. Our key advantage is maintaining a fully stocked sheet metal and fabrication shop to meet our customer’s needs, whether it is on a moment’s notice or a large planned-out project. Our teams can handle any project of any size to get the job done. We have experience installing dust collection systems, exhaust and ventilation systems, roof top, split or ductless systems, chiller systems, refrigeration piping, environmental chambers and computer/server room systems.

To request a quote for your next HVAC system, call us at 888-833-8776 or request a free quote here.

Subscribe and receive updates via email

“Lee Contracting believes a strong community is best built and sustained through the involvement of the local businesses and the citizens of the communities in which they reside.” Ken Labruyere, CEO of Lee Contracting. With many of Lee Contracting’s customers calling Detroit home, we feel that we are not only corporate citizens of Pontiac, but of the entire Metro Detroit area.

This year, Lee Contracting partnered with the Detroit RiverFront Conservancy to become a friend sponsor for the Conservancy’s largest annual fundraiser, Shimmer on the River. The event raises money to help with developing, operating and maintaining costs of Detroit’s riverfront.

“Shimmer on the River is a celebration of the Detroit Riverfront,” said Mark Wallace, president & CEO of the Detroit RiverFront Conservancy. “The proceeds from the event help to ensure that the Detroit Riverfront remains a clean, safe, and beautiful gathering place for everyone.”

The event which took place on June 22, 2017, transformed the riverfront into a family fun fair and a carnival complete with free carnival games and rides. The evening started with a VIP reception followed by a strolling dinner and musical entertainment. At 8:00 p.m. guests were treated to a special performance by The Temptations Review.

Shimmer on the River served as a kickoff for GM’s River Days event which ran June 23-25 2017.  The Detroit RiverFront Conservancy started the River Days festival in 2007 as a way to show off the newly transformed Detroit International Riverfront to the community and visitors.

The Detroit RiverFront Conservancy started the River Days festival in 2007 as a way to show off the newly transformed Detroit International Riverfront to the community and visitors.

The Detroit RiverFront Conservancy was started in 2003 to develop a world-class public space in downtown Detroit. Their vision is to transform the 5.5 miles of riverfront property from the Ambassador Bridge to Gabriel Richard Park into a continuous Riverwalk with plazas, pavilions, and green spaces.

Lee Contracting is excited to be a part of not only helping with Pontiac’s revitalization but also with Detroit’s. We understand that a strong Detroit means a strong metro area, which benefits everyone who lives, works, plays, and vacations in the area. Without the help of the local businesses and corporations, the riverfront area would not be on the track it is now to become a destination for everyone in the area to enjoy for years to come.

Subscribe and receive updates via email

Lee Industrial Contracting is an established company founded in 1989 in Pontiac, Michigan. We specialize in a wide array of project types including rigging, We are an exciting, cutting edge company to work for, not just in the Pontiac area, but in the US.

Our wide variety offerings in services allow us to continually be on the forefront of technological development in the field of industrial contracting. Our biggest draw for clients is our capability to be a full Turn-Key solution to their needs. We have all our staff and crew entirely in-house. This allows us to be efficient and work on areas where we can do better with ease of communication. This results in a high client and employee satisfaction ranking.

We believe that if our employees are happy then our clients have a higher chance of being satisfied with our services as well. We have an unwavering commitment to worksite safety to ensure that the workplace is a place YOU want to be. This is backed up by the fact that we are a 100% employee owned company!

We believe that if our employees are happy then our clients have a higher chance of being satisfied with our services as well. We have an unwavering commitment to worksite safety to ensure that the workplace is a place YOU want to be. This is backed up by the fact that we are a 100% employee owned company!

Check out our current career openings or give us a call at 888-833-8776 for more information if you’re ready to join an award winning team!

Subscribe and receive updates via email

When you decide to learn a skilled trade, there are several trades you can learn. Pipefitters work in many different industries from commercial and residential to manufacturing plants and oil refineries.

Here are six reasons why you should consider a pipefitting career.

- The pipefitting field is growing. Through 2022, pipefitting and plumbing fields are expected to grow 21 percent. This is faster than the average growth rate of other fields. Currently, there are not enough pipefitters to sustain the industry growth, which is good news for those considering becoming a pipefitter.

- The career is steady. With a faster than average projected industry growth rate, there is plenty of work for a pipefitter. They can work in any field from

residential to commercial to industrial.

residential to commercial to industrial. - You could start earning money quickly. Instead of attending a 4-year college, you can attend a technical training program. These programs will help you gain field experience and enter the field quickly. To become a pipefitter, most people start out with no experience as an apprentice. After 5 years of training, you can be a highly skilled valuable professional.

- The position pays well. As a pipefitter apprentice, you can start earning money while you are training to be a pipefitter. The average pipefitting apprentice in Michigan makes $34,850. While the average Michigan salary for a pipefitter is $75,200. The return on investment is pretty high considering the cost of a typical 4-year college degree.

- You can increase your salary with overtime work. While you will enjoy a steady 40-hour work week, you will also be able to work in the evenings and on weekends for overtime. With a high demand for pipefitters, especially in the oil and gas industries, there will be ample opportunities for overtime work.

- You could receive excellent benefits. Most pipefitting jobs provide excellent benefits including paid time off and health insurance. The access to these benefits can enhance your quality of life.

As the industry grows and the demand for pipefitters, pipefitting is an excellent career choice for anyone who is interested in a steady career that is both personally and financially rewarding.

At Lee Contracting, we offer our customers turn-key solutions for plant projects. We have our own in-house staff of electricians, pipefitters, HVAC installers, fabricators and more. We currently have several open skilled trades positions available. Apply today: https://www.leecontracting.com/careers/

Subscribe and receive updates via email

Electricity is essential on every one of our job sites. It is sometimes called the “silent partner” on the job. It supplies the power needed to run tools and machines, it provides lighting, and it powers heaters and air conditioning units. When used safely and properly, electricity makes our lives easier.

Electricity is essential on every one of our job sites. It is sometimes called the “silent partner” on the job. It supplies the power needed to run tools and machines, it provides lighting, and it powers heaters and air conditioning units. When used safely and properly, electricity makes our lives easier.

Electricity has also been called the “silent killer” because you don’t hear, see, taste, or smell it. If you use electricity carelessly or recklessly, if you overlook the many hazards it presents, you may be setting yourself up for injury or death from burns, falls, shocks, or electrocution.

To protect yourself from the hazards of electricity, keep the following safe work practices in mind:

- Visually inspect electrical hand tools and extension cords before each use.

- Immediately remove defective tools and cords before using.

- Always wear the necessary PPE and use grounded or double-insulated tools.

- Never handle an electrical tool by its power cord.

- Only use extension cords that are rated for hard or extra hard use. Codes like S, ST, SO, STO, SJ, SJT, SJO & SJTO should be printed on the cords.

- Take care of extension cords. Keep them out of the way to prevent damage.

- Never yank cords to disconnect them. Reach down and pull the plug from the receptacle.

- Don’t try to repair electrical cords or tools unless you are qualified and authorized to do so. Repairs should only be made by qualified electricians.

- If you are authorized to make repairs, make sure you follow lockout/tagout procedures.

- When working in damp or wet areas, only use tools protected by a ground-fault circuit interrupter (GFCI).

- Never operate electrical tools or equipment while standing in water.

- Never use makeshift wiring.

- Use 3-prong receptacles. Never break off the ground to fit an underground outlet.

- Keep equipment and activities at a safe distance (at least 10 feet) when working around power lines.

All of our electricians attend classes in NFPA 70E and MIOSHA Parts 33 & 40 “Electrical Safe Work Practices” instructional programs to ensure we are doing everything we can to prevent electrical injuries. We design, quote, layout, and execute electrical installations to follow electrical safe work practices. We provide high levels of PPE and test equipment for protection.

All of our electricians attend classes in NFPA 70E and MIOSHA Parts 33 & 40 “Electrical Safe Work Practices” instructional programs to ensure we are doing everything we can to prevent electrical injuries. We design, quote, layout, and execute electrical installations to follow electrical safe work practices. We provide high levels of PPE and test equipment for protection.

Whether you are at home or at work working with electricity remember to practice electrical safety and keep electricity as a silent partner in your projects.

Subscribe and receive updates via email

As summer rapidly approaches and the weather heats up, heat stress becomes a daily concern for everyone. Iowa State University defines heat stress as “a series of conditions where the body is under stress from overheating.” Not only are those who work outside at risk for heat stress-related illnesses, but the elderly and children are at risk too.

As summer rapidly approaches and the weather heats up, heat stress becomes a daily concern for everyone. Iowa State University defines heat stress as “a series of conditions where the body is under stress from overheating.” Not only are those who work outside at risk for heat stress-related illnesses, but the elderly and children are at risk too.

There are several behaviors that increase the likelihood of heat stress. Those include drinking alcohol, strenuous outdoor activity, certain medications, and wearing inappropriate clothing for the heat and humidity. High air temperatures, radiant heat sources, high humidity, and direct physical contact with hot objects also have a high potential for inducing heat stress.

When the body is unable to cool itself by sweating, several heat-induced illnesses such as heat exhaustion and heat stroke can occur and can result in death. Tracy, our safety coordinator has some tips on how to spot heat stress and what to do if someone has heat exhaustion or heat stroke:

Factors Associated with Heat Stress

Factors Associated with Heat Stress

- High temperature and humidity, direct sun exposure, no breeze or wind

- Low liquid intake

- Heavy physical labor

- Waterproof clothing

- No recent exposure to hot workplaces

Symptoms of Heat Exhaustion

- Headache, dizziness, or fainting

- Weakness and wet skin

- Irritability or confusion

- Thirst, nausea, or vomiting

Symptoms of Heat Stroke

- May be confused, unable to think clearly, pass out, collapse, or have seizures (fits)

- May stop sweating

Most often, the signs of heat stress are missed by the victim. Everyone should be aware of the symptoms. There are several steps you can take if you suspect someone has heat exhaustion or heat stroke:

- Call 911 or the designated emergency number for your site

- Move the person to a cool, shaded area

- Loosen or remove heavy clothing

- Provide cool drinking water

- Fan and mist the person with water

When working on a job site there are several steps you can take to help prevent heat stress. The CDC recommends allowing workers to acclimate to the hot temperatures, set up a buddy system, schedule and encourage frequent breaks, emphasize the need for appropriate clothing and encourage workers to drink fluids, 1 cup every 15 to 20 minutes. These actions will help to protect everyone on your team from heat stress.

When working on a job site there are several steps you can take to help prevent heat stress. The CDC recommends allowing workers to acclimate to the hot temperatures, set up a buddy system, schedule and encourage frequent breaks, emphasize the need for appropriate clothing and encourage workers to drink fluids, 1 cup every 15 to 20 minutes. These actions will help to protect everyone on your team from heat stress.

Heat related illness is not to be taken lightly, it can become a very serious situation in a short amount of time. If something doesn’t feel right, it’s probably not. Be safe, stay hydrated and keep cool!

Subscribe and receive updates via email

When you are planning to expand or grow your industrial facility rigging is a very important part of the process. You need to trust the team in which you are entrusting your largest and most expensive assets. This team needs to understand several key aspects of the job before the heavy lifting even begins.

Rigging can Dangerous

Rigging can  be quite a dangerous task. Lifting and moving thousands of pounds is a specialized job that requires extensive knowledge and planning. Understanding the scope of the project and the safety concerns are of utmost importance. The riggers you hire should be backed up by years of experience and be willing and able to provide you with references. Their knowledge will help to keep everyone and everything safe throughout the project.

be quite a dangerous task. Lifting and moving thousands of pounds is a specialized job that requires extensive knowledge and planning. Understanding the scope of the project and the safety concerns are of utmost importance. The riggers you hire should be backed up by years of experience and be willing and able to provide you with references. Their knowledge will help to keep everyone and everything safe throughout the project.

Experienced Personnel

Before your project kicks off, your contractor should be able to meet all your needs for the project. Everyone including the account manager, project manager, estimator, and riggers should have the technology and experience to help the job run smoothly. They should make you feel comfortable about the job from the onset.

Insurance

Moving heavy equipment should not be taken lightly. Your rigging contractor should have insurance to protect the equipment while they are handling it. While everyone works to prevent accidents and damage, incidents do happen.

Equipment

Your rigging contractor should have an extensive fleet of equipment they use to complete a project. Some of their equipment will include forklifts, gantries, die carts and a mobile crane. All of this will help to make completing your project easier. If you are moving equipment over the roadway, you should check out their fleet of trucks to ensure they have trucks that can support the transportation of your machinery.

Your rigging contractor should have an extensive fleet of equipment they use to complete a project. Some of their equipment will include forklifts, gantries, die carts and a mobile crane. All of this will help to make completing your project easier. If you are moving equipment over the roadway, you should check out their fleet of trucks to ensure they have trucks that can support the transportation of your machinery.

When it comes to choosing a rigging contractor for your next equipment move you should make sure they fulfill all your needs. Turn to Lee Contracting for your next project and we will not disappoint. Our in-house equipment and over 25 years’ experience will leave you feeling confident in our ability to meet your timelines and budget. Request a quote today, or call us to learn more 888.833.8776.

Subscribe and receive updates via email

In 2015, Lee Contracting expanded its capabilities to include machine repair. Adding machine repair to our core capabilities was a natural progression for our company. We were already handling the utilities, transportation and rigging of presses in-house. We wanted to grow our company to truly become an indispensable asset for your industrial projects.

Our machine repair crews are highly experienced in maintaining, troubleshooting, repairing and rebuilding your machinery. Our teams utilize the best in-house equipment to upgrade and refurbish your equipment.

Our equipment includes:

We have a Giddings & Lewis CNC boring machine with an 89” vertical travel, 168” cross travel and a 72” by 170” table.

Our CNC and manual lathes have the capacity up to 32” diameter and 120” length.

Our Blanchard grinder has a 60” capacity.

Our Blanchard grinder has a 60” capacity.

Our Faro ion laser tracker allows us to  reverse engineer components for your equipment needs.

reverse engineer components for your equipment needs.

We offer our customers full portable machining capabilities, including milling, boring, bore welding, facing and keyway cutting. This allows us to control downtime and save you money. We can also design and implement preventative maintenance programs to fit your facility’s needs.

With the addition of this new division comes the need to staff it. We are currently looking to fill four open positions; Machine Repair Journeyman, Industrial Maintenance Technician, Machinist and Industrial Maintenance Technician (Hydraulics).

With the addition of this new division comes the need to staff it. We are currently looking to fill four open positions; Machine Repair Journeyman, Industrial Maintenance Technician, Machinist and Industrial Maintenance Technician (Hydraulics).

According to the Bureau of Labor Statistics, the job growth outlook for machinery mechanics and machinery maintenance workers is favorable. The average growth rate for all occupations is 7 percent, however, the growth rate for machinery mechanics is 16 percent between 2014 and 2024.

If you are interested in becoming an industrial machinery mechanic, you should have a steady hand, good hand-eye coordination, mechanical skills and troubleshooting skills. Most mechanics receive on-the-job-training for more than a year. During training, you will learn a variety of skills, including setting up, cleaning, lubricating, starting machinery, shop mathematics, blueprint reading, hand tool use, welding, electronics and computer programming.

With the need for machine repair growing, we are keeping up with our customer’s demands by adding and growing our machine repair division. We are looking for qualified candidates to fill our open positions.

We aim to be your industrial turn-key solution.

Subscribe and receive updates via email

What do you do?

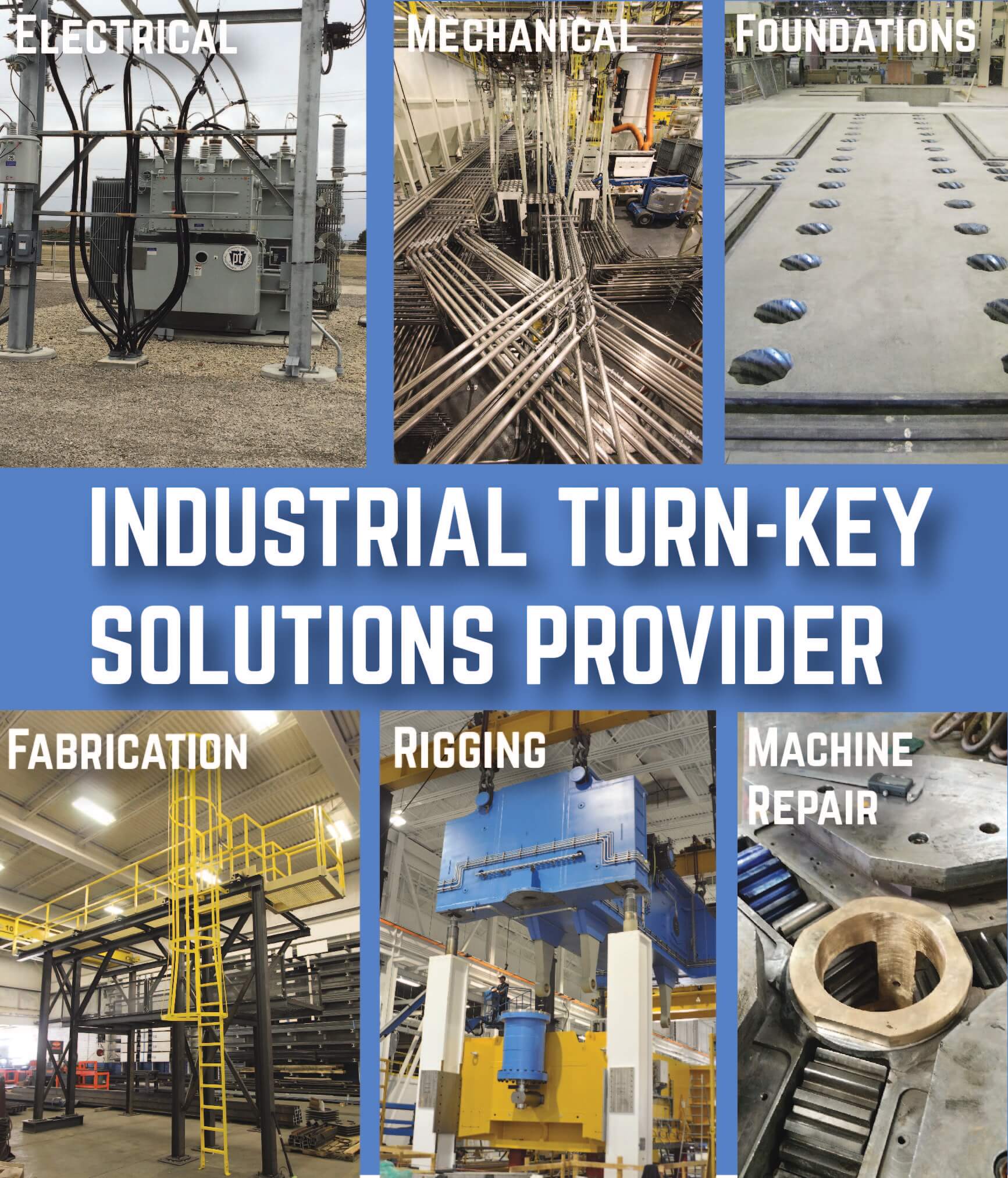

We are a single-source contractor who specializes in turn-key projects. We can handle every aspect of your next industrial project. We have the capabilities to move machinery around your plant, across the street or across the country. We handle every aspect of the project in-house.

Our core capabilities include Electrical, mechanical, rigging, foundations, fabrication and machine repair.

To complement these capabilities we also offer transportation, carpentry, controls and robotics, roof raising, emergency power, and specialty lifting and transport.

Are you a general contractor?

No. We have an in-house staff of skilled tradesmen who self-perform all the work on a job site. This allows us to control project costs and work on accelerated timelines.

How many people do you employ?

We have over 350 employees. We employ people in a range of trades including riggers, electricians, HVAC, pipefitters, foundations craftsmen, fabricators, machine repairmen, controls and robotics, and carpentry.

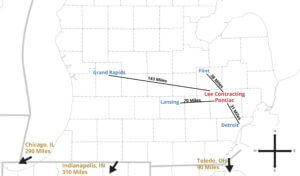

Where are you located?

We are conveniently located in Pontiac, MI, about 31 miles northwest of Detroit. We are uniquely positioned to service several key manufacturing hubs.

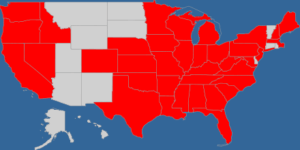

I have a project in Kentucky, do you work there?

Yes. In addition to Kentucky, our field employees have traveled all over the country. See the map to the right for every state in which we have worked.

Yes. In addition to Kentucky, our field employees have traveled all over the country. See the map to the right for every state in which we have worked.

We also have worked in several countries across the world, including Canada, Mexico, Thailand, Philippines, and Turkey.

How long have you been in business?

We were established in Clarkston in 1989. Six years later Lee Contracting was incorporated and we moved to Pontiac, MI with 10 employees. Today, we have over 350 employees and are employee owned.

Are you hiring?

Yes. We have several open positions listed on our website. We are always looking for hardworking, dedicated and ambitious employees.

Subscribe and receive updates via email

Since 1992, employers have participated in Take Our Daughters to Work Day. In 2003, the day was expanded to include boys and became known as Take Our Daughters and Sons to Work Day. This day is a chance to show kids “the value of their education,” and to help them “discover the power and possibilities associated with a balanced work and family life.”

This years’ event was hosted on Thursday, April 27, 2017. Lee Contracting had over 20 kids participating for the day. The day started with a snack and a speech from our CEO, Ken Labruyere. The kids had a chance to hear how important their parents are to Lee Contracting.

This years’ event was hosted on Thursday, April 27, 2017. Lee Contracting had over 20 kids participating for the day. The day started with a snack and a speech from our CEO, Ken Labruyere. The kids had a chance to hear how important their parents are to Lee Contracting.

Up next, our safety department talked about the proper safety equipment everyone should wear while on a job site. The proper safety gear includes hearing protection, safety glasses, hard hats, gloves and safety vests.

Our safety department also explained how a press works. The kids were given pedometers and talked about the distance a flywheel travels per day. They were told a fly wheel can travel more than 1,500 feet per shift. That’s more than one lap around a track.

The kids also had an opportunity  to be introduced to several pieces of our equipment. They could climb up (with spotters) and sit in a semi-truck, excavator and a skidsteer. At this point, the parents joined their kids for pictures by the equipment and a group picture in front of our 300T Grove Crane.

to be introduced to several pieces of our equipment. They could climb up (with spotters) and sit in a semi-truck, excavator and a skidsteer. At this point, the parents joined their kids for pictures by the equipment and a group picture in front of our 300T Grove Crane.

After a lunch break of pizza and salad, the kids were tasked with putting together a wooden press. They were given all the necessary supplies to build the press including blocks, screws and pipe cleaners.

After working hard to build a press, the kids had some well-deserved down time to play on the football field at Wisner Stadium and finished their day with snow cones.

The day was a hit with the kids. Whether they enjoyed sitting in the semi-truck, building the wooden presses or eating snow cones best, the kids all enjoyed themselves.

We look forward to next year’s event.

residential to commercial to industrial.

residential to commercial to industrial.