Category: Blog

Skilled trades are a critical part of the nation’s workforce. The economy is improving and as baby boomers rapidly approach retirement, the need for tradespeople to replace them is continuing to increase. Many of these positions are in the industrial field. Here are four types of in-demand industrial careers and Lee Contracting’s open positions in the field.

- Electrician

Electricians install, repair, and maintain electrical wiring and equipment. Growth in the construction industry will mean more demand for electricians. At Lee Contracting, we currently are hiring: an electrical apprentice, master/journeyman electricians, journeyman electricians and an electrical estimator.

- Carpenter

Carpenters can be involved in many different aspects of construction. They can do anything from framing walls and setting concrete forms to building bridges and installing cabinets. Growth in the industrial field will boost the demand for carpenters over the next few years. Lee Contracting is currently looking to hire a building department estimator.

- Industrial machinery mechanic

This career is expected to have much faster-than-average job growth between 2016 and 2026—as machinery gets increasingly sophisticated, more mechanics will be needed to keep the equipment in good working order. Lee Contracting is currently hiring the following positions for their maintenance and repair department: machinist, industrial maintenance technician, machine repair journeyman, industrial maintenance technician-hydraulics and a field machinist.

- Heavy truck driver

Most of the freight in the U.S. is transported by truck. Heavy truck drivers are needed to move goods from one place to another. Lee Contracting is hiring a CDL-A driver with 2 years of experience and a clean driving record.

Subscribe and receive updates via email

Lee Contracting’s Industrial Maintenance department offers a full range of services to keep up with your company’s ever-changing needs. It is becoming increasingly important for companies to constantly produce in order to please consumers. Companies are now facing little to no downtime with taking on larger workloads and the demand to constantly produce. Lee’s goal is to maintain your production schedule and ease the overall process to accommodate your company and employees.

When you choose Lee for your Industrial Maintenance you will receive:

- 24/7 emergency service

- Predictive, preventive and corrective maintenance

- Equipment maintenance including:

- Conveyer rebuilds

- Cylinder rebuilds

- Pump rebuilds

- Component replacements

At Lee we understand how valuable time and energy is to a company. As a result, our efforts to maintain production schedules will increase equipment lifespan, increase productivity, and ultimately increase savings.

We take great pride in our work and will always deliver quality service to our customers. Call us today to request a free quote at 888-833-8776 or visit our website here for a quote.

Subscribe and receive updates via email

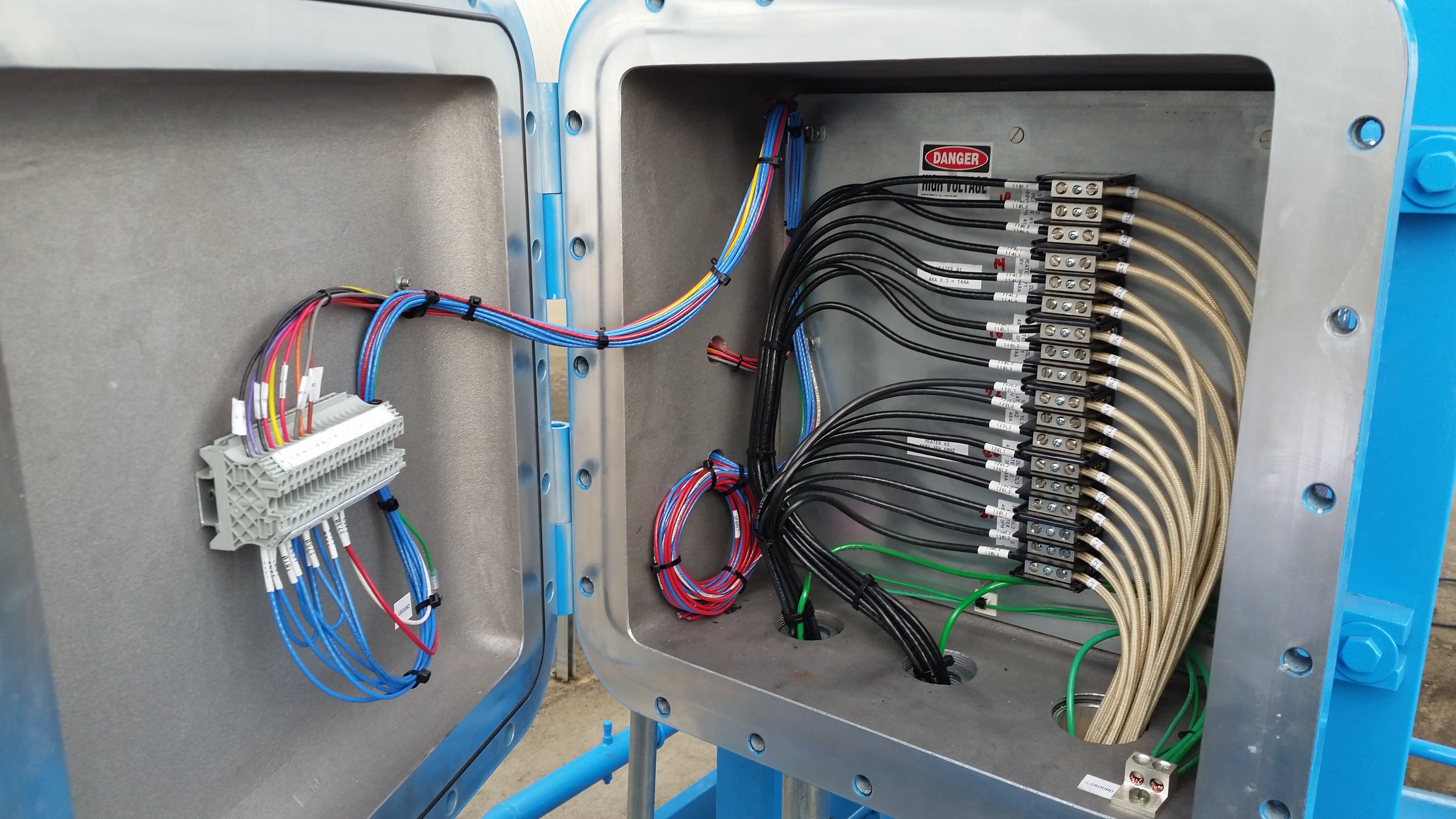

Lee Contracting’s electrical department has been around since the beginning. Lee Contracting originally started in 1989 as Lee Electric in Clarkston, MI. Just 6 years later, Lee Electric became Lee Contracting and moved to Pontiac, MI. Our electrical department today continues to offer the best electricians and service in the industry.

Our electrical staff is complete with master electricians who can provide services ranging from routine plant maintenance all the way up to major electrical renovations. They use industry-leading modern equipment which helps to keep our employees on the job instead of in the repair shop. Our key advantage is keeping a large electrical supply in-house for a quicker job turnaround and emergency service response.

All our electricians are continually educated to stay current with code changes and new installation techniques. We train our apprentices through the Michigan State University apprenticeship program. This program allows our apprentices to gain on the job training and work experience while learning the theoretical and technical knowledge needed to become a successful journeyperson.

Lee’s highly skilled electrical department provides our customers with a wide range of capabilities including:

- Installment standby generators: backup lighting panels, UPS systems, and whole service backup power.

- Emergency generator services: 24/7, 365 days a year.

- Design and installation of primary power.

- 24/7, 365 days a year emergency repair to get your shop back up and running, minimizing your downtime.

- Control wiring specialist: from wiring upgrades to complete machine rewire.

- Complete industrial installation: electrical design, motor controls and transformers.

- Power quality monitoring: monitoring equipment to help determine and repair power quality issues.

- Infrared imaging: determine predictive maintenance.

- Complete commercial and industrial lighting installation.

Call us today at 888.833.8776 to take advantage of our electrical department’s capabilities. Or you can request a free quote on your next electrical project here.

Subscribe and receive updates via email

With winter now in full swing, we have some tips for staying safe while working during the colder and snowier months.

When working on a roof:

When working on a roof during the winter there are several conditions that could be hazardous to workers. Make sure the area is inspected for safety before work begins on the roof. Slippery surfaces due to temperature drops, hidden skylights or electrical hazards from overhead power lines or snow removal equipment all pose a risk to employees. Training on how to use the correct PPE and equipment for the job can protect workers from unnecessarily working in hazardous conditions.

Prevent Slips:

Snow and ice cause surfaces to become slippery and hazardous to everyone. To minimize the risk of slipping and falling, employees should wear water-resistant boots with good rubber treads on them while walking on slippery surfaces. Walking at a slower pace and taking shorter steps will also allow you to react if there is a change in traction.

Vehicle Safety:

Many employees drive company vehicles or operate mechanized equipment every day.  Employers should ensure that the vehicles are in proper working order. Several systems should be inspected including: the break system, cooling system, electrical system, exhaust system and visibility systems. The oil level and tire inflation levels should also be checked.

Employers should ensure that the vehicles are in proper working order. Several systems should be inspected including: the break system, cooling system, electrical system, exhaust system and visibility systems. The oil level and tire inflation levels should also be checked.

Make sure to also complete these safety checks on your personal and family’s vehicles too. It is a good idea to keep an emergency kit in your car.

A car emergency kit should include:

- Cellphone or two-way radio

- Windshield ice scraper

- Snowbrush

- Flashlight with extra batteries

- Shovel

- Tow chain

- Traction aids (bag of sand or cat litter)

- Emergency flares

- Jumper cables

- Snacks

- Water

- Roadmaps

- Blankets, change of clothes

The cold and snow make working conditions more treacherous. However, following these OSHA tips can help minimize the risks employees face during the winter season.

Subscribe and receive updates via email

2017 was another successful year here at Lee Contracting. We accomplished so much and are so thankful to our employees, customers, and vendors who help us remain a leading industrial turn-key solutions provider.

Let’s look back at some of the events over the last year that helped us to get where we are today:

- The year started off with a new contract between Lee Contracting and the Pontiac School District. We added 6 employees who oversee the preventative maintenance for the HVAC, electrical and plumbing systems for 11 district buildings.

- In March, there was a windstorm that knocked out power to several customers and local businesses. Lee Contracting helped them stay online through the use of our emergency power generators. Without these generators, many of these businesses would have lost money waiting for the power to be turned back on at their facility.

- Lee Contracting joined the Specialized Carriers & Rigging Association in April. We are now part of an association of more than 1,300 members from 46 nations who “specialize in

transportation, machinery moving and erecting, industrial maintenance, millwrighting and crane, and rigging operations.”

transportation, machinery moving and erecting, industrial maintenance, millwrighting and crane, and rigging operations.”

- Lee Contracting celebrated Take Your Child to Work day at the end of April. We had over 20 kids attend and learn about the many different aspects of the industrial field. The kids were treated to a day full of fun activities and learning.

- July brought with it a chance to partner with the

Detroit Riverfront Conservancy. Many of our customers call the city of Detroit home. We were excited to be able to participate in Shimmer on the River which helps to ensure the Detroit Riverfront “remains clean, safe and beautiful for everyone.”

Detroit Riverfront Conservancy. Many of our customers call the city of Detroit home. We were excited to be able to participate in Shimmer on the River which helps to ensure the Detroit Riverfront “remains clean, safe and beautiful for everyone.”

- In August, Lee Contracting was recognized by

Inc. 5000 magazine as one of the fastest growing privately owned companies in America. This was our second straight year on the list. This year we moved up the list to #2925.

Inc. 5000 magazine as one of the fastest growing privately owned companies in America. This was our second straight year on the list. This year we moved up the list to #2925.

- We also lunched our internal leadership program in August. This program has helped to foster a team environment and increase employee engagement.

- Lee hosted our 2nd Annual Golf Outing which helped to raise over

$10,000 dollars for Detroit’s Focus:HOPE. Our donation supported their skilled training program.

$10,000 dollars for Detroit’s Focus:HOPE. Our donation supported their skilled training program.

- In November, Lee Contracting attended FABTECH in Chicago, IL.

The show allowed us to meet and network with industry leaders from across the country.

The show allowed us to meet and network with industry leaders from across the country.

2017 was a busy and successful year for Lee Contracting. We look forward to see what 2018 has in store for us.

Subscribe and receive updates via email

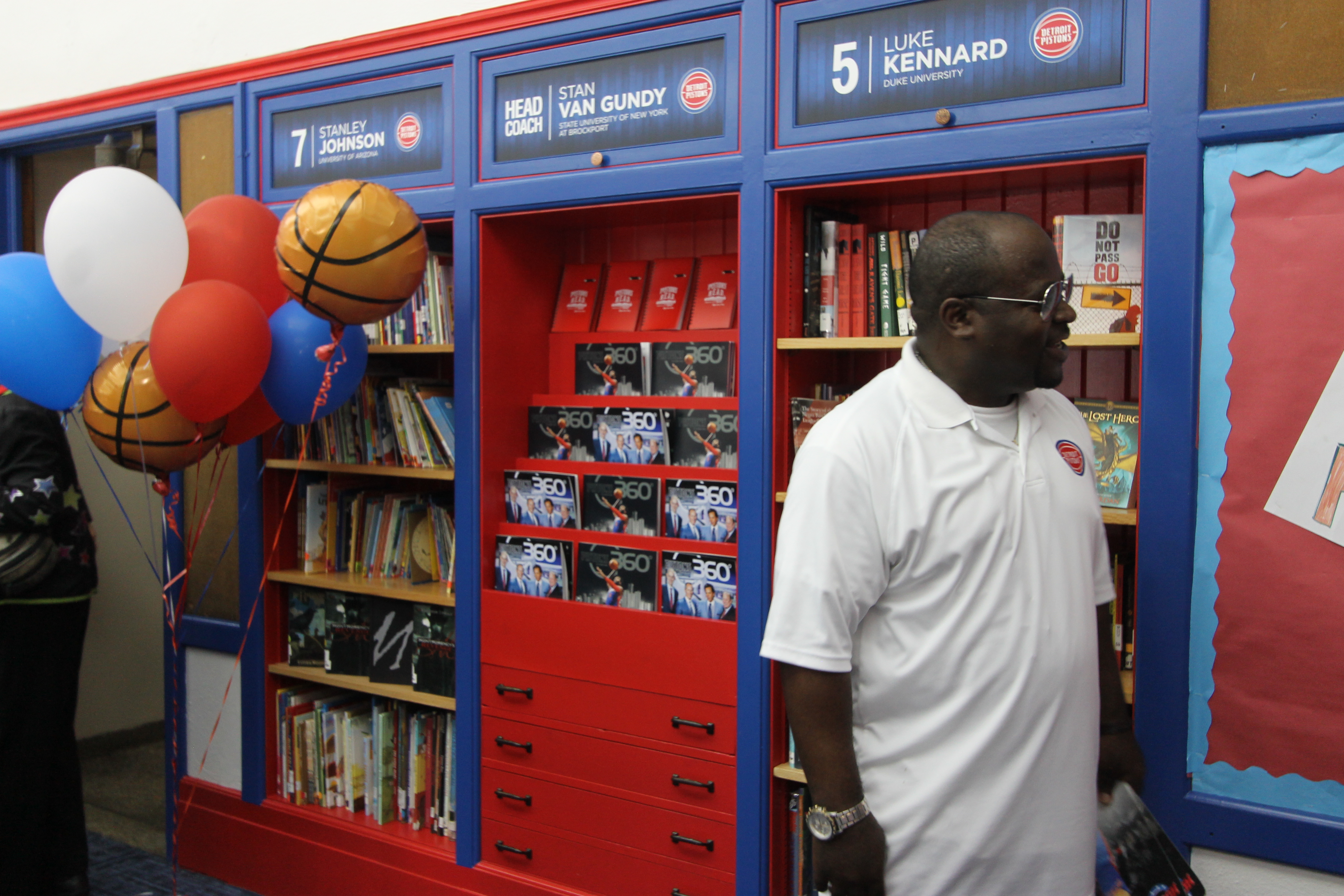

This past September, the Detroit Pistons unveiled a new library at J.E. Clark Preparatory Academy in Detroit, Michigan. It was admired by the students and staff of the school along with officials from the Pistons, Farm Bureau, Detroit Schools, and former Detroit Pistons player, Earl Cureton. After 7 years without a functional library, the school was gifted a beautifully updated Pistons themed library with the help of Lee Contracting.

Over the last four years, Lee Contracting has partnered with the Pistons and The Palace to perform work at their many entertainment venues in the Metro Detroit area. Lee Contracting has worked at the Palace and DTE Energy Music Theater completing several renovations over the years. These renovations included: installing new lighting in the Pistons training center, rebuilding truck dock platforms, building stage extensions at DTE, renovating the blue room, and rebuilding the loading docks at Meadow Brook Amphitheater. Lee’s core capabilities are rigging, electrical, foundations, mechanical, fabrication and maintenance and repair.

All the necessary tasks that went into completing the

Pistons vision for the library were done with the multi-skilled dynamic that Lee performs. Skills performed in this transformation included reconstructing missing pieces of the original foundation such as the benches and shelving units, refinishing the wood, installing new flooring and light fixtures. Lastly, painting the library in the Pistons theme all while keeping the original integrity of the space.

“Lee Contracting was excited to partner with the Detroit Pistons on the J.E. Clark Preparatory Academy library project. We value the opportunity to give back to the community in which we work and play. Knowing that our hard work will inspire generations of students to learn makes this a memorable project,” says Brian Rausch, Project Manager for Lee Contracting.

Visit our website to find out more about how Lee Contracting can help successfully transform your business.

Subscribe and receive updates via email

The extreme cold weather during winter in Michigan can make it difficult for employees who work outside to stay warm throughout their day. Not taking the necessary precautions to stay warm can put the employee at risk for developing several types of cold stress including hypothermia, trench foot, or frostbite. Follow these tips to stay safe and warm while working outside this winter:

- Wear layers of clothing

If you are working outside, it’s important to dress in layers to stay warm. Wear quality warm clothing such as thermal undergarments, insulated pants, coats, and overalls. Make sure that your layers are long enough to cover your waist when you are bending or reaching while working. All clothing should allow adequate blood flow. If you get sweaty, consider removing a layer because inactivity after sweating can cause you to become cold again. To keep your feet warm, double up on socks and make sure your boots are thick and properly insulated.

-

Wear gloves

Wear gloves

When working outside, choose gloves that will protect your hands from the wind and that have good insulation. Some fabrics, like leather, are very helpful in blocking the wind, and the thin, insulated layer allows you to move your fingers while remaining warm.

- Keep your feet and head covered

Cold weather can be especially harmful in these areas. Wear insulated and water-resistant boots, as well as a  warm hat and, if necessary, a facemask. Make sure your ears are covered.

warm hat and, if necessary, a facemask. Make sure your ears are covered.

- Keep moving

Moving around, even on your downtime, will help you to stay warm. Do some form of physical activity, such as stretches, jumping jacks or pacing.

- Work in pairs

Working in the extreme cold, it is a good idea to work in pairs or a team. This allows other people to watch for the initial subtle symptoms of cold stress. Intense shivering and confusion are among the most common signs.

- Consume hot beverages

Drinking warm beverages like coffee and tea throughout the day will help to keep you warm and fight the cold-induced lethargy.

- Eat a warm lunch

Eating a warm lunch will help warm your body up and keep you warm as you continue to work through the rest of the day.

By taking the necessary precautions to stay warm while working outside during the winter, you will be able to diminish your risk of hypothermia, trench foot, and frostbite.

Subscribe and receive updates via email

Flint Michigan and Lee Contracting

Lee Contracting’s Turn-key solution approach to projects often leads us all over the world. With its deep historical manufacturing base, Flint, Michigan provides numerous opportunities for Lee Contracting to showcase its capabilities.

Flint, Michigan

Flint, Michigan is the largest city in Genesee County, Michigan. It is located on the Flint River, fewer than 66 miles northwest of Detroit. It is one of the oldest cities in Michigan, having been incorporated in 1855. It is the seventh largest city in Michigan in terms of population.

In the 19th century, Flint became one of the leading manufacturers of carriages. As the use of carriages gave way to automobiles in the mid-20th century, Flint became known as “Vehicle City”. Despite a decrease in vehicle manufacturing in the mid-2000s, Flint, with its manufacturing heritage, is still a city that many different manufacturing factories call home.

Below, are summaries of two customers in Flint who utilized Lee Contracting’s turn-key services.

American Spiral Weld and Lee Contracting in Flint Michigan

American Spiral Weld needed a steel pipe processing line transported from Istanbul, Turkey to its manufacturing facility in Flint. The move involved a turn-key installation of a 400-foot metal processing line and a spiral mill.

American Spiral Weld needed a steel pipe processing line transported from Istanbul, Turkey to its manufacturing facility in Flint. The move involved a turn-key installation of a 400-foot metal processing line and a spiral mill.

The biggest hurdle Lee Contracting ran into with this project was the fact that the equipment had been sitting dormant in Turkey for four years! But Lee came through with flying colors for American Spiral by performing repairs amounting to approximately $1.5 million using custom engineered and fabricated parts to ensure the successful operation at their Flint, Michigan manufacturing facility.

Moving from Flint Michigan

Steel Technologies had a blanking line in Flint, MI that needed to be removed, transported and reinstalled in Madison, Mississippi. This move would include performing any machine repair needed to get them properly installed as well as painting them to fit new facility colors.

Steel Technologies had a blanking line in Flint, MI that needed to be removed, transported and reinstalled in Madison, Mississippi. This move would include performing any machine repair needed to get them properly installed as well as painting them to fit new facility colors.

Prior to installation at their new facility, Lee Contracting installed a new 20-foot-deep foundation for the blanking line. At this depth, we were hitting the water table and needed to pump water out of the pit before pouring the foundation. The machines also had to be reprogrammed to integrate together as they were originally programmed to automatic function.

Time and time again Flint, Michigan has provided Lee Contracting with unique and challenging opportunities to prove its Turn-key Solution advantage.

Give us a call at 888-833-8776 or request a quote to see how Lee Contracting can meet your needs in Flint, Michigan.

Subscribe and receive updates via email

This is part 5 of a 5-part series.

Last week’s blog talked about the fourth step to a successful equipment relocation: Transporting. This week, we are focusing on the final step: Installing

Installing

The last step in ensuring you have a successful press move is the installation of the press. Hiring the right riggers can make a world of difference during the installation process. The right rigging company will have the proper equipment for the job, including: cranes, gantries, fork trucks and man lifts.

The equipment’s new location will have its own set of challenges compared to its previous location. These might include:

- There might not be a pit or foundation installed for the equipment. (Lee’s foundation department can install one for you.)

- Lower ceiling heights, which requires the riggers to use special assembly procedures (Lee can raise the roof over the new equipment location.)

- The doorways might not be large enough which would require the machinery to be either disassembled or for the doorway to be made larger. (Lee’s building department can enlarge any doorway to suit your needs.)

- Power supplies to the building might not be large enough to handle the new equipment. (Lee has journeymen and master electricians on staff to upgrade your power supplies.)

- Air compressors might not be large enough to handle the new requirements. (Lee’s air compressor department can install and upgrade your current air compressor system.)

These challenges should have been discussed and solved during the planning process. Lee Contracting’s turn-key solutions process takes the time to ensure that you are not surprised with one of the above issues during the installation process. We think of everything to make sure you are up and running as fast as possible.

Lee Contracting knows that investing in new equipment is a huge undertaking. We work with you to complete the project safely, efficiently and in a timely manner. We take your trust in us very seriously and strive to be a world-class industrial contractor.

Call us today for a free RFQ at 888.833.8776 or click here to submit one online.

Subscribe and receive updates via email

This is part 4 of a 5-part series.

Last week’s blog talked about the third step to a successful equipment relocation: Servicing. This week, we are focusing on the fourth step: Transporting

Transporting

Planning the transportation of your press is a critical step. The weights and dimensions of the machinery and its components are essential when it comes to estimating transportation costs. The best way to find the weights of the components is from the original equipment manufacturer.

Planning the transportation of your press is a critical step. The weights and dimensions of the machinery and its components are essential when it comes to estimating transportation costs. The best way to find the weights of the components is from the original equipment manufacturer.

Most large machinery exceeds the weight capacity of a standard five-axle tractor/ trailer combination. Oftentimes, when transporting heavy equipment, higher-capacity transport equipment must be specified, routes must be established, and special permits must be obtained. Depending on the state, some permits may take four to six months to obtain.

When planning transportation,  you should also take into consideration the destination of the equipment. The destination will help to determine which transportation equipment is needed, which permits are required and the preparation and packaging requirements. Some states have different requirements for overweight and over dimensional loads, so it is imperative to find equipment that can meet the requirement of all states through which the loads must travel.

you should also take into consideration the destination of the equipment. The destination will help to determine which transportation equipment is needed, which permits are required and the preparation and packaging requirements. Some states have different requirements for overweight and over dimensional loads, so it is imperative to find equipment that can meet the requirement of all states through which the loads must travel.

Lee Contracting has over 25 years’ experience and a full team of experts, who have the capabilities to complete all your required services as a single-source contractor throughout the United States.

Check back next week for the final part in this series on how to have a successful equipment move.

For a free quote on relocating a press or any piece of equipment, call us today at 888.833.8776 or click here.

Interested in joining our team? Apply online today.

Interested in joining our team? Apply online today.

transportation, machinery moving and erecting, industrial maintenance, millwrighting and crane, and rigging operations.”

transportation, machinery moving and erecting, industrial maintenance, millwrighting and crane, and rigging operations.”

Inc.

Inc.  $10,000 dollars for Detroit’s

$10,000 dollars for Detroit’s  The show allowed us to meet and network with industry leaders from across the country.

The show allowed us to meet and network with industry leaders from across the country. Wear gloves

Wear gloves