Category: Fabrication

Industrial fabrication has entered a new era: one where machines don’t just assist humans, they redefine what’s possible. A team of robotic arms working in harmony. Automated guided vehicles gliding across factory floors. Computerized systems making split-second decisions to optimize efficiency. This isn’t the future – it’s the now.

For companies seeking industrial fabrication services, automation and robotics are reshaping operations. They bring increased precision, speed and safety to fabrication processes, allowing businesses to achieve more with less.

In this article, we’ll have a look at how these technologies are creating new possibilities for fabrication projects.

Why Industrial Fabricators Are Turning to Automation and Robotics

Automation and robotics are transforming how industrial fabrication services are delivered, resulting in a number of benefits for manufacturers, including:

- Consistency: With automation, tasks are performed precisely the same way every time, reducing the likelihood of errors commonly found in manual processes.

- Speed: Robotic systems accelerate repetitive tasks, speeding up production without sacrificing quality. Automated assembly lines can handle large-scale projects more quickly than traditional methods.

- Safety: Industrial environments typically involve risks such as exposure to extreme temperatures or dangers with heavy machinery. Automation reduces the need for human involvement in hazardous tasks, along with the potential for injuries.

- Cost: Automation can reduce costs by streamlining production processes, minimizing errors and increasing throughput, which leads to lower labor expenses and less material waste.

Applications of Robotics and Automation in Fabrication

Modern automation now goes beyond simple mechanization. It leverages advanced technologies such as AI, machine learning and real-time data analytics to make operations smarter and increase facility capabilities.

Here are some specific applications of modern automation and robotics:

Welding and cutting

Robotic arms equipped with precision tools can handle intricate welding or cutting jobs quickly and accurately.

Material Handling

Automated Guided Vehicles (AGVs) transport materials on a specified route through a facility while Autonomous Mobile Robots (AMRs) can recognize obstacles and change course automatically.

Custom Fabrication

Robotics can be programmed to create customized solutions, such as creating unique components with complex geometries while ensuring uniformity in high-volume production runs.

What’s Next for Industrial Fabrication Services

While current automation and robotics practices may seem mind-blowing, this is only the beginning. The future will bring further advancements, such as AI-driven robotics that optimize processes in real-time to IoT-enabled systems that monitor machine performance. AGVs and AMRs, for instance, are already revolutionizing how materials are handled in fabrication plants, improving facility layout efficiency and operational flow.

We also expect to see developments in automated inspections and 3D printing that will expand the potential of industrial fabrication services, allowing companies to take on even more complex and high-stakes projects.

By embracing these technologies, forward-thinking businesses may be able to achieve safer operations, faster delivery times and high-quality results.

If you’re ready to bring the benefits of automation to your next project, partner with experts who stay ahead of industry trends. Lee Industrial Contracting offers advanced solutions that deliver precision and efficiency for every job.

Contact us today to learn how we can help your business succeed in this evolving landscape.

Subscribe and receive updates via email

One of the most common questions we get from customers inquiring about our industrial fabrication services is “How long is the lead time?” It’s understandable, of course, because the time it takes to complete the project can affect production schedules and have a ripple effect on your entire operation.

Luckily, the team at Lee Industrial Contracting has engaged in numerous industrial fabrication projects and knows from experience what it takes to cut down on lead times. Let’s review how we can ensure a smooth project and timely completion.

Plan Early

One step that should never be overlooked is early, detailed planning. Planning ahead allows all parties to anticipate issues that might create bottlenecks and devise plans to avoid or mitigate them. Begin by clearly defining the project requirements and specifications. Involve all stakeholders from the beginning to ensure everyone is on the same page. Being proactive enables us to schedule appropriately and allocate the necessary resources to minimize the risk of delays.

Turn-key Industrial Fabrication Services

Working with a team that has every capability in-house can significantly reduce lead times. When a single company handles each aspect of a project – including engineering design, build, transport and installation – processes are streamlined due to better coordination, communication and control over the timeline.

By contrast, working with multiple contractors means navigating multiple schedules, project leads and opinions on how the work should be completed. This approach often leads to delays in trying to get all parties on the same page. Companies with in-house capabilities like Lee Contracting manage every aspect of the project, leading to seamless coordination. Teams that are 100% in-house also adapt more quickly to changes and unexpected challenges, so your project is more likely to stay on track.

Lee Contracting offers a comprehensive range of industrial fabrication services, all in-house:

- Design and engineering

- Custom 2D and 3D design

- Design certification by structural engineers

- AWS D1.1-certified welders

- Fully equipped welding and fabrication shop

- Full machining capabilities

- Final paint in-house or on-site

- Large fleet of rigs to transport any size or weight

- 24-hour emergency service

Advanced Equipment & Technology

Investing in state-of-the-art equipment and technology goes a long way to ensure a faster turn on projects. Modern design software that utilizes 2D and 3D modeling techniques accelerates projects with precise visualizations, identifying potential issues early in the design phase and facilitating smoother transitions from design to fabrication. This leads to fewer revisions and errors that affect project speed.

Advanced equipment ensures higher precision and faster rates of production. For instance, modern cutting machines, welding systems, and CNC (Computer Numerical Control) machines deliver more efficient and accurate fabrication processes. State-of-the-art equipment allows fabricators to handle complex tasks more efficiently, leading to quicker turnaround times.

Experienced Teams

While proper planning, in-house capabilities and advanced equipment play key roles in reducing lead times, none of it matters without a skilled and experienced team leading the way. With 35 years of experience managing and executing industrial fabrication services, there’s almost nothing our team hasn’t done. This experience, combined with continuous skill development in the latest fabrication techniques and technologies, is what enables us to navigate even the most complex challenges efficiently and deliver on time.

Need industrial fabrication services for an upcoming project? Talk to a Lee Contracting team member for a quote.

Subscribe and receive updates via email

In today’s rapidly evolving manufacturing landscape, we at Lee Industrial Contracting understand the importance of reliable partners who can help navigate complexities with efficiency and expertise. Since 1989, we have distinguished ourselves with our unique turn-key approach, which is strengthened by our experience and innovation. Our comprehensive solutions lay the groundwork for success, empowering industries to thrive in the robust manufacturing sector.

The Turn-Key Advantage

We are proud to be the only truly in-house, turn-key industrial contracting firm in the industry. This model consolidates a wide range of trades under one roof, offering our clients simplified workflows and cost-efficient outcomes. By managing everything from design, building, installation and maintenance, we provide a seamless, single-source solution for complex industrial challenges.

Expertise Across Sectors

One of our core strengths is our ability to handle projects of varying complexities. Our in-house team and comprehensive resources eliminate the need for multiple subcontractors, streamlining project execution and enhancing quality control. This approach is not only efficient but also cost-effective, striking a balance between functionality and budget constraints.

Diverse Services, Unified Excellence

Our range of services is as diverse as it is specialized:

- Electrical: With master electricians and extensive in-house inventory, we guarantee timely and quality electrical project completion.

- Pipefitting: We excel in fabricating and installing process piping, HVAC and compressed air systems.

- Foundations: Our proprietary processes and capabilities ensure world-class foundation work.

- Rigging: Our industry-leading equipment and technical know-how enable us to analyze, plan, move and reassemble your next rigging project

- Fabrication: We offer custom 2D/3D design, installation, and machining services, even on-site.

- Maintenance & Repair: Our specialized capabilities in predictive, preventive, corrective and emergency maintenance are a cornerstone of our services.

The Power of Employee Ownership

A pivotal aspect of our identity at Lee Industrial Contracting is our employee ownership structure. This model fosters a culture of personal investment and commitment to excellence, benefiting not just our employees but also our clients through higher project productivity and growth.

Conclusion

In an era where manufacturing in Michigan is thriving, our turn-key solutions and diverse expertise are more relevant than ever. By providing comprehensive services and efficient, value-driven solutions, we empower industries to not just navigate but excel in today’s dynamic manufacturing landscape. Our commitment to quality, efficiency and innovation under the ‘Power of One’ philosophy is a testament to our role as a trusted partner for industrial projects throughout the midwestern region and across the United States.

Subscribe and receive updates via email

Do you like to problem solve? How about creating things from scratch? If so, have you ever considered a career in industrial fabrication? Let’s take a closer look at some frequently asked questions to discover what it takes to be a fabricator at Lee Contracting.

1. How can I become a fabricator? After you earn a high school diploma, or equivalent:

- You can apply for a fabricator apprentice opening at Lee, where workers will receive on-the-job training.

- Some aspiring fabricators choose to self-educate by taking classes such as Blueprint Reading for Welders (https://www.vdci.edu/blueprint-reading-bundle), or other welding courses to learn the trade before beginning full-time. Please note: this is not a requirement to begin your career as a fabricator at Lee.

- Many people start out in one of Lee’s 13 different in-house trades and wish to learn the art of welding. We are committed to providing team members opportunities for growth, and employees can be transferred into the fabrication department to give them the opportunity to learn a new skill.

- If you have a passion for making things, as well as a good work ethic, that’s all that’s needed to be a successful welder at Lee.

2. What certifications are required? Lee does not require any certifications to become a fabricator. However, having more welding certifications may allow you to stand out as a more valuable employee.

3. What types of projects do industrial fabricators work on? One of the best parts about working at Lee is the diversity of projects. Some other fabricators specialize in certain industries (aerospace, structural steel, machine building, etc.), and others specialize in working with a specific material (mild steel, stainless steel, aluminum, heavy plate, etc.). However, our fabricators do it all!

4. What are the different types of industrial fabrication jobs at Lee? In Lee’s weld/fab department, there are a variety of roles. We have equipment operators, fabricator apprentices, fabricators, fabricator foreman and install foreman. Even some of our former fabricators have grown in the company to become estimators, who play a crucial role in our new business process.

5. How can a welder stay safe on the job? Safety is a top priority at Lee. The first step in any fabrication project is to identify potential hazards and working toward eliminating or minimizing those risks before starting production. We also require our fabricators to wear all of the necessary Personal Protective Equipment and Clothing (PPE) to keep safe on the job.

6. What is it like working as a fabricator at Lee? A fabricator at Lee can expect to be challenged daily, with the intent to grow and expand their craft. Lee is one of the best places to be a fabricator due to the diversity of the work; you never know what you may be building next! At the end of the day, being a fabricator at Lee is challenging, yet fun and rewarding.

Interested in a career at Lee? Learn more about what it’s like to work at Lee and view our current job openings here: https://www.leecontracting.com/careers/

Subscribe and receive updates via email

There are many options for heating and air conditioning units for industrial and commercial use. Lee Industrial Contracting is among the most trusted and well-respected industrial HVAC companies in and around Michigan. We are proud to be your choice of HVAC contractors to help you understand the many choices and select the right system for your company’s needs.

Split System Condensing Units

What differentiates a split system from other HVAC systems is that it is composed of an indoor air handler with the condenser and compressor in a metal enclosure outdoors. Unlike packaged units, the air handler with fan and evaporator coil is separate from the condenser and compressor. There are both single and multi split systems.

Single Split Systems

The single split system is a prevalent choice for business owners. They are affordable and compact, making it ideal for small offices, restaurants, shops and server rooms. Installation is much less than centralized units. Since they operate independently, the failure of any one unit to perform does not impact any other areas.

The single split HVAC system typically consisted of an air conditioner to cool and a furnace to convert the refrigerant. An evaporator coil circulates the air. The unit is controlled with a thermostat or similar control panel.

Multi Split Systems

Where single split units have one indoor unit for every outdoor unit, multi split systems can have accommodated up to nine indoor units for every outdoor unit. This is a more aesthetically pleasing choice and better for buildings with limited exterior space. However, because it requires more ductwork, installation is higher as compared to a single split system.

This configuration is highly energy efficient, using inverter technology to allow the compressor to operate at variable speeds. The highest energy usage in commercial systems comes from the compressor turning on and off. With the use of sensors and heat pumps, the multi split system can identify areas that need adjustment and move warm air from one area to another cooler area.

VRF Systems

Variable refrigerant flow or VRF HVAC systems are good choices for medium to large office buildings or hotels. There are two types of VRF systems. Heat pump VRF systems can either heat or cool, but it can’t do both simultaneously. It is appropriate for open floor plans. A heat recovery system is a better option for multiple rooms or offices, as it can provide heat to one while cooling another at the same time.

Direct Fired Air Handlers

These heavy-duty air units are built to last with the base, frame and wall panels welded into one unibody cabinet. They are energy efficient, delivering 100% of the burner power into the heated space. Indoor air quality is maintained by the introduction of fresh outside air into the system. Up to 80% of the air can be recirculated, reducing your energy costs.

Indirect-Fired Air Handlers

Indirect fired or IDF air handling units pressurize an area with conditioned outdoor air. You have the option to heat, cool or recirculate the conditioned air. Carbon monoxide, a natural by-product of combustion, is directed outside the space during the heating mode. It is a highly energy-efficient option.

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

Features of an Industrial HVAC System

Some features that may be found in an industrial HVAC system include:

- Heating systems such as electric heat, boilers, furnaces and heat pumps

- Ventilation and dust collection

- AC units including rooftop units, direct expansion units, chillers and heat pumps

- Thermostats

- Sensors

- Automation systems

Heating, ventilation and air conditioning systems play an essential role in industrial operations. They condition the air for worker comfort and to safeguard mechanical and electronic equipment. The ventilation system is vital for filtering out dust, dirt, chemical and other contaminants from the air. Dust collection systems are frequently integrated into the overall HVAC system to improve and maintain air quality. By separating the air filtering, it allows the HVAC system to work more efficiently.

Ductwork is a critical component in any industrial HVAC system. Materials can include galvanized, stainless or rolled steel. The design, fabrication, operation and maintenance must consistently and reliably meet the regulations for air quality standards, as well as building codes. It also plays a role in maintaining a safe workplace. That’s why it is critical for you to choose from knowledgeable, experienced local HVAC contractors.

Sensors, thermostats and automation systems provide energy efficiency. Requirements for heating, cooling and ventilating an empty building can vary significantly from times when the facility is fully staffed and operating normally. Sensors can monitor air quality, temperature and occupancy, as well as air pressure to optimize system operations and notify maintenance when there is a problem.

Benefits of Using Experienced Local HVAC Contractors

The cost of using inexperienced installers can be significant. Poorly designed, fabricated or installed HVAC systems can use more energy, reduce productivity and result in low air quality. Substandard air quality can not only impact employee health that results in more frequent absenteeism, but if left unchecked, it could endanger lives and put your business at risk.

Advantages of using an industry-leading provider for sheet metal fabrication, installation, service and preventative maintenance needs include:

- Cost savings

- Improved air quality

- Superior energy efficiency

- Optimized design for your facility

- Certified, licensed professionals

- Adherence to regulatory requirements, building codes and industry standards

What to Look for in an HVAC Contractor

Commercial and manufacturing environments have very different needs for their HVAC systems than residential uses. Industrial HVAC systems can be very complex, depending upon the functions and the size of the facility. When your business is at stake, you can’t afford to take the lowest bid. You need to carefully vet your contractor and ensure that you get the expertise required for quality materials, installation and maintenance.

Lee Industrial Contracting is a 100% employee-owned company, meeting and exceeding our customers’ expectations with turn-key solutions for over 30 years. Our capabilities include:

- Installation of standby generators, including backup lighting panels, UPS systems and whole service backup power

- 24/7 emergency generator services available365 days a year

- Design and installation of primary power by certified electricians

- 24/7 emergency repair to minimize your downtime 365 days per year

- Specialists in control wiring, from wiring upgrades to complete machine rewire

- Comprehensive industrial installation, including electrical design, motor controls and transformers

- Monitoring of power quality, including monitoring equipment to help determine and repair power quality issues

- Infrared imaging to determine predictive maintenance

- Complete lighting installation for commercial and industrial applications

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

To the untrained eye, a commercial construction site and an industrial construction site may not look very different. In fact, most people use the terms interchangeably. Professionals who work in both construction types know there are challenges and processes that are unique to each type. The key is looking beyond the obvious similarities to find the specific factors that set them apart.

Permitting Process

Most big construction projects require some type of permitting. In some jurisdictions, even putting up a sign may attract the legal attention of local officials. Commercial construction permitting tends to focus on zoning requirements, general safety and occupancy requirements. Once met, a business can open its doors with ease.

Of the two construction types, industrial sites have more compliance factors to take into consideration. This is especially true if the company handles, stores or manufacturers hazardous material. Satisfying these guidelines, in addition to commercial guidelines, can tack on weeks or months to the process. It may also necessitate specialized expertise.

Site Planning

Once construction companies have the green light to start working, it’s time to create a plan for how the construction site will play out. At this point, the lead contractor will meet with the client to determine what the most important concerns are. Engineers will then need to determine the best way to work around these design flaws.

Both construction types want to limit how construction affects operations as much as possible. The difference is in the how. Commercial construction site planning focuses on keeping businesses accessible to customers and presentable to the public. Industrial construction sites are less concerned about being presentable and more focused on logistics, such as power consumption allocation.

Design Process

The design process is one of the most exciting parts of the project for the client and the contractor. It allows both parties to blend needs and wants and bring ideas to life. However, the design language for a business frequented by the public or consumers is much different from the industrial design language. The fact that many commercial spaces are taking on industrial aesthetics does little, if anything, to change this.

For both construction types, traffic flow is important, but the reasons are different. Commercial construction sites need to prioritize the easy and functional flow of traffic to maximize how long customers spend in spaces and encourage lingering. Industrial construction designs favor floorplans that prioritize the following:

- Keeping traffic moving

- Reducing lingering

- Enhancing productivity

- Improving efficiency

Infrastructure Support

Commercial construction sites do not differ terribly from how homes are constructed. In fact, some commercial construction sites are for long-term or short-term residential use, such as hotels, nursing homes and apartment buildings. The infrastructure generally includes HVAC systems, the ability to control smaller ecosystems within the whole and some provisions for larger power consumption.

Of the two construction types, manufacturing requires the strongest supporting infrastructure. This includes not just provisions for massive power consumption, but also waste management. This can drastically change the materials and expertise required.

Project Management

Most project managers can handle the average commercial construction site. The contractors they hire may also not differ much from what is required for larger residential projects. For instance, project managers may need to focus on organizing plumbers, electricians and interior designers.

Both construction types require these skill sets, but industrial construction sites also require advanced and specialized skills. These may include large-scale installations, equipment assembly and custom fabrication. Project managers may also need to handle the complex logistics systems that may become necessary to move oversized loads when plants expand or move locations.

Without a doubt, industrial and commercial construction sites are very similar. Even so, the main distinguishing factors for both construction types can all be tied back to priorities, functions and logistics.

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

Planning a fabrication project is no small undertaking and requires a lot of planning and forethought. As you begin this process, you must consider things like budget, schedule, design and implementation. There are numerous steps along the way, and while some may seem small, if they’re not completed, might cause delays. If you’re ready to begin a new project, find out how Lee Industrial Contracting can provide excellent industrial fabrication services to ensure your success.

To help you understand what we offer in our services, here are the main phases of an industrial fabrication project, and why each of them is critical to the process.

Engineering Design

As you start your project, you’ll be working with our in-house engineers. The first step is to communicate what your end goal is; what final product you are looking for. Your project could be for a new set of stairs in your lab facility, a mezzanine designed and installed in your warehouse, or a structural steel layout for your shipyard. Whatever you require, our designers will deliver a high-quality design.

While the final goal is important, we also need to know if there are any constraints on the project. We will need to know of any legal statutes, regulatory compliance, spec requirements or load limits tied to your final product. All of these are important pieces of information that our engineers will need to keep your project in compliance. All designs are checked by structural engineers to ensure soundness.

The design phase is the most important part of your project. Our engineers will work closely with you to ensure the design is right the first time and that you are satisfied with the result.

Manufacture and Build

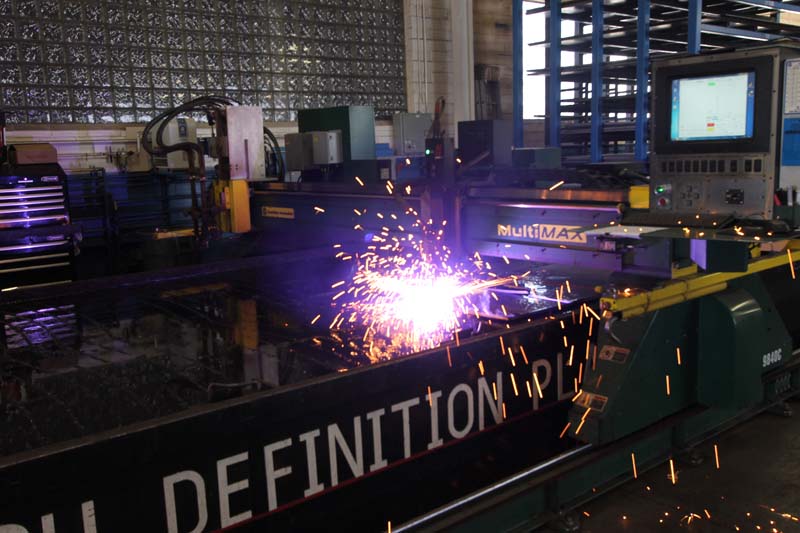

After the design is complete, it’s handed off to our manufacturing and building team. This professional group will be responsible for cutting metal to specifications using our HyDefinition Plasma Machine and OMAX waterjet cutting machine.

Once the metal is cut to spec, it will be manipulated – if needed – into the desired shape. This step often involves using one of our presses, employing our Baileigh tube bender and using other specialized equipment.

Next, we begin the build process. This may either be a complete build for smaller projects or a partial build for larger projects that need final assembly on-site. Using our fully equipped welding rigs, with AWS D1.1 certified welders, we carefully assemble the product to match the specifications of the design team.

Every step of the manufacture and build process is inspected to ensure it meets welding codes and conforms to the design.

Treatment and Assembly

Corrosion treatment and final assembly will depend on the size of the project, as noted above. For small projects, we will fully assemble the product, then apply our corrosion protection treatment and final paint. This is all done in-house, before transportation.

For larger projects, final assembly won’t occur until individual pieces are transported to the install site. Once onsite, we will do final assembly, including all necessary welding. After an inspection for design conformance and welding codes, we will apply corrosion treatment and paint.

When you work with our industrial contracting company, you receive first class customer service from the design phase until final assembly.

Contact Lee Industrial Contracting Today

You won’t find a company that is more dedicated to providing you a high-quality product and a great experience than Lee Industrial Contracting. If you’re ready to begin your industrial fabrication project, or if you have any questions about the process, we’re ready to answer. Please reach out to us today through our web form, or give us a call at (888) 833-8776. Our qualified team of engineers and professionals is ready to answer your questions and start you on the road to a successful project.

Subscribe and receive updates via email

A career in metal fabrication is a rewarding, exciting and lucrative one. The benefits to this growing field include steady employment, solid income potential, and the opportunity to work on a wide variety of projects.

Career Outlook

The U.S. Bureau of Labor Statistics reported that fabricator employment rose 2.3% in 2016. The average hourly wage of $19.23 per hour and a mean annual wage of $40,000 makes a career in fabrication an excellent choice. Fabricator jobs account for 1.8 million in today’s workforce. If you are a fabricator, you can find employment in several different industries. These include: industrial, transportation, shipping, motor vehicle, body and trailer manufacturing, engines and turbines, aerospace and rail transportation.

The U.S. Bureau of Labor Statistics reported that fabricator employment rose 2.3% in 2016. The average hourly wage of $19.23 per hour and a mean annual wage of $40,000 makes a career in fabrication an excellent choice. Fabricator jobs account for 1.8 million in today’s workforce. If you are a fabricator, you can find employment in several different industries. These include: industrial, transportation, shipping, motor vehicle, body and trailer manufacturing, engines and turbines, aerospace and rail transportation.

What do Fabricators do?

Most metal fabricators work for a fabrication company or in a manufacturing plant. Metal fabricators utilize raw metals and machinery to fabricate, position, align and fit metal products for a large variety of products and industries.

Skills and Training

Typically, the minimum education for a fabricator requires a high school diploma followed by technical training. The technical training will include hands-on learning of fabrication fundamentals including: safety, blueprint reading, math, MIG/TIG/stick welding, sheet metal fabrication, part constructing/forming and project building. These skills and theories of metal fabrication are critical to success in the field. A great training program will provide education and hands-on training using state-of-the-art equipment.

Our People

Lee Contracting employs an unparalleled staff of skilled craftsmen and state-of-the-art equipment to best serve our customers. Our experienced fabrication crews work closely with our other in-house departments to create high-quality work that delivers.

You can view and apply for our current job openings here. We are a 100% employee-owned company offering great benefits including 401k, health insurance and paid vacation.