Category: Foundations

In today’s rapidly evolving manufacturing landscape, we at Lee Industrial Contracting understand the importance of reliable partners who can help navigate complexities with efficiency and expertise. Since 1989, we have distinguished ourselves with our unique turn-key approach, which is strengthened by our experience and innovation. Our comprehensive solutions lay the groundwork for success, empowering industries to thrive in the robust manufacturing sector.

The Turn-Key Advantage

We are proud to be the only truly in-house, turn-key industrial contracting firm in the industry. This model consolidates a wide range of trades under one roof, offering our clients simplified workflows and cost-efficient outcomes. By managing everything from design, building, installation and maintenance, we provide a seamless, single-source solution for complex industrial challenges.

Expertise Across Sectors

One of our core strengths is our ability to handle projects of varying complexities. Our in-house team and comprehensive resources eliminate the need for multiple subcontractors, streamlining project execution and enhancing quality control. This approach is not only efficient but also cost-effective, striking a balance between functionality and budget constraints.

Diverse Services, Unified Excellence

Our range of services is as diverse as it is specialized:

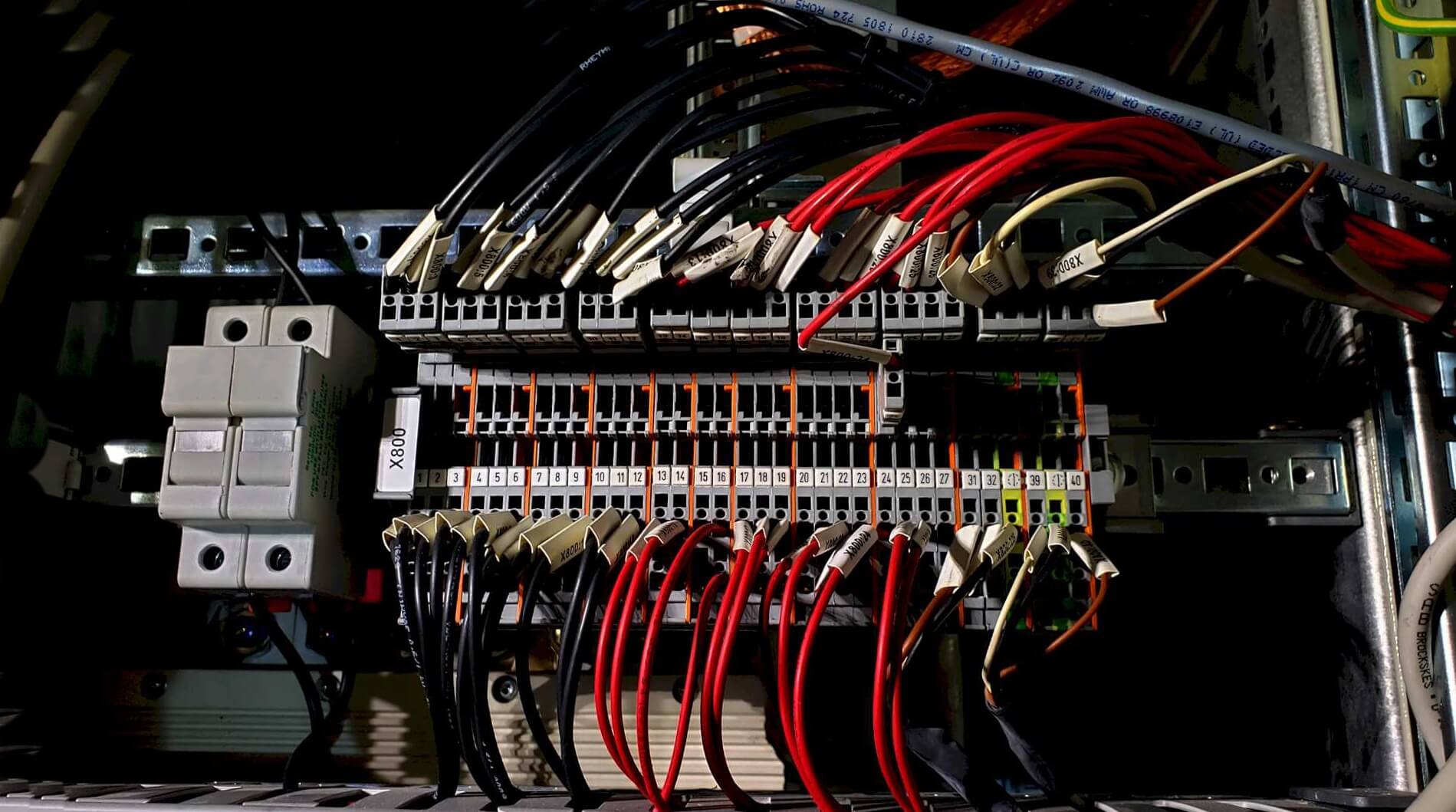

- Electrical: With master electricians and extensive in-house inventory, we guarantee timely and quality electrical project completion.

- Pipefitting: We excel in fabricating and installing process piping, HVAC and compressed air systems.

- Foundations: Our proprietary processes and capabilities ensure world-class foundation work.

- Rigging: Our industry-leading equipment and technical know-how enable us to analyze, plan, move and reassemble your next rigging project

- Fabrication: We offer custom 2D/3D design, installation, and machining services, even on-site.

- Maintenance & Repair: Our specialized capabilities in predictive, preventive, corrective and emergency maintenance are a cornerstone of our services.

The Power of Employee Ownership

A pivotal aspect of our identity at Lee Industrial Contracting is our employee ownership structure. This model fosters a culture of personal investment and commitment to excellence, benefiting not just our employees but also our clients through higher project productivity and growth.

Conclusion

In an era where manufacturing in Michigan is thriving, our turn-key solutions and diverse expertise are more relevant than ever. By providing comprehensive services and efficient, value-driven solutions, we empower industries to not just navigate but excel in today’s dynamic manufacturing landscape. Our commitment to quality, efficiency and innovation under the ‘Power of One’ philosophy is a testament to our role as a trusted partner for industrial projects throughout the midwestern region and across the United States.

Subscribe and receive updates via email

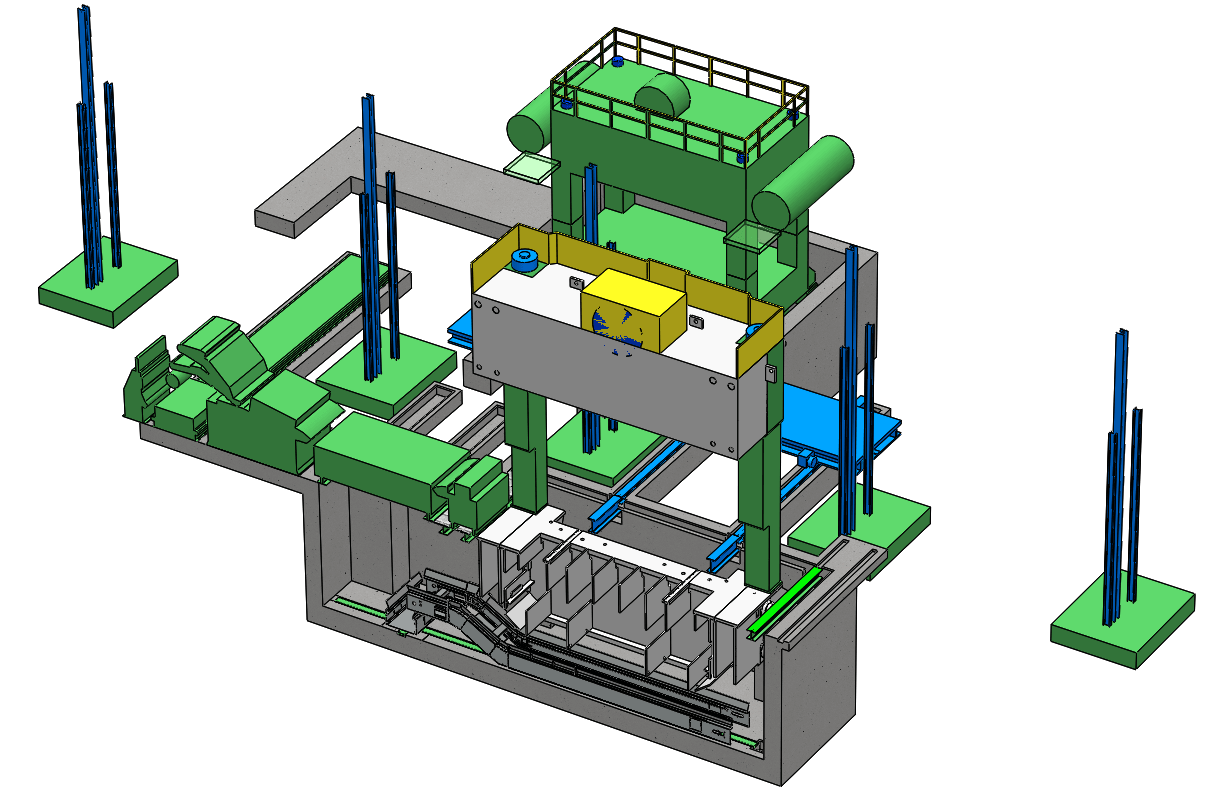

3D modeling has changed the way design and planning is done in a variety of industries. It provides a perspective and level of detail that 2D modeling just can’t do.

Lee Contracting utilizes 3D modeling to better help our clients visualize their project. How do we do that? Find out below.

What is 3D modeling and how is it used for foundations?

At Lee Contracting, our engineers use SolidWorks, a CAD-based program, to create digital 3D models of before our team even steps foot on the job site.

The process begins when our experienced team receives a general assembly drawing from one of our clients. Next, our skilled engineers create the client’s vision in 3D by integrating their new plan, and their secondary equipment, into one overall design. This helps ensure all the equipment and machinery will work together properly (i.e., mapping trench measurements and routing in the foundations to support all secondary equipment).

Our engineers color code the model to indicate a change in materials, departments, machinery, etc. After the model is finished, a PDF version of the proposed plan is exported and presented to our client.

What are the benefits?

There are several advantages to engineering a 3D project model prior to beginning large, design-build foundations jobs.

- Saves Time: By creating a 3D project model, any potential issues/challenges can be caught before even breaking ground. This allows Lee’s team to go into the project with an efficient plan which has an extremely low probability of error. This saves our teams from having to problem solve on the spot and/or reverse any work that has already been done.

- Saves Money: Since 3D project models help to eliminate errors, this lowers costs as materials and working time are not wasted due to errors.

- Allows for more accurate quoting: 3D modeling helps our estimators accurately quote the project. The model outlines the exact materials and work needed for the job.

- Easy viewing for clients: The 3D model can be exported from SolidWorks to a PDF, so anyone with Adobe Acrobat Reader can have a 360-degree view on the model.

What are the challenges?

While 3D modeling for foundations projects has many benefits, our engineers are faced with challenges along the way. Many clients have a proposed budget already in place for their project, and it’s up to our engineers to design a plan that fits within the client’s budget. Depending on the works that needs to be done, our engineers do their best to find the most cost-effective solution to meet our client’s needs.

3D project modeling is a service not many other industrial contractors offer; however, the process has been perfected by the engineers at Lee. Request a quote today to get your 3D plan started: https://www.leecontracting.com/request-a-quote/

Subscribe and receive updates via email

Shutdowns. Layoffs. Plant closures. Projects on-hold. And now, shortage-driven price inflation. The global pandemic has thrown the entire world into chaos.

In the industrial contracting space, the most noticeable problem in recent months has been price and supply volatility in materials. According to the U.S. Chamber of Commerce, 84% of contractors face at least one material shortage. And for 46% of industrial contractors, material shortages are having a high impact on projects.

A Perfect Storm

When the pandemic took hold in 2020, shutdowns across the board brought the nation, the economy and our industry to a near standstill. Almost overnight, many industrial contracting projects were put on hold, although work did continue in regions of the country where construction was considered an essential industry. Those projects that did move forward faced extended lead times and often severe restrictions on how work was performed.

From the start, manufacturers began shutting down operations. This quickly led to shortages of materials for construction. The effects were highlighted in steel production, as mills were closed around the world.

With the easing of restrictions, buyers have seen the basic law of supply and demand showcased, in that as demand for materials exceeds supply, prices rise accordingly. In industrial construction, demand is still running ahead of supply, fueled by owners who are scrambling to restart projects that had been put on hold. Additionally, companies are also moving rapidly to get new projects underway.

Even with the challenges, the construction industry has been somewhat less affected than many others. Many industrial contractors are experiencing high workloads, both in backlogged work from 2020 and projects whose timelines have been accelerated.

A New Normal?

The short-term situation has seen major changes in the way projects unfold, especially in the bidding process. Because of pricing volatility, the old norm of 30-60-90 day quotes has been replaced by quoted prices that are now only good until the end of the day due to the rapidity of price changes. The effects are felt on both the owner and contractor side, introducing a level of uncertainty not seen before in heavy industrial construction.

Project owners and industrial contractors don’t expect the situation to ease for at least another year. And even as supplies slowly become more available, labor shortages continue to delay projects. For example, it’s not unusual for loaded trucks to sit for weeks before delivery, due to a lack of drivers. At least in the short term, price and supply volatility are expected to be the norm.

The appearance of the Delta variant has once again put the nation on edge. Its effects on the reopening of the U.S. economy are, of course, currently unknown. But even if the variant should have a significant impact, the effects are not expected to be as severe as those of the original pandemic, because industrial contractors and suppliers have learned how to operate effectively under adverse conditions.

A Light in the Tunnel

As industrial contractors closely monitor the ever-changing construction landscape, supply challenges are being addressed by aggressive increases in materials inventories. Leading firms with solid relationships with suppliers and strong buying power are maintaining higher inventory levels and working with stakeholders to keep them up to date on supply and price issues.

This is a boon for project owners, who can benefit from partners that have seen the writing on the wall and made significant inventory investments. Contractors who are unable or unwilling to risk increasing their materials inventory will likely be less competitive going forward.

In addition to our massive in-house inventory, Lee Contracting has a dedicated team of buyers scouring the world for the best combinations of price and supply, ensuring we have the inventory available now to complete your project without delay. Contact us today to discuss the benefits to your next project.

Subscribe and receive updates via email

There are many options for heating and air conditioning units for industrial and commercial use. Lee Industrial Contracting is among the most trusted and well-respected industrial HVAC companies in and around Michigan. We are proud to be your choice of HVAC contractors to help you understand the many choices and select the right system for your company’s needs.

Split System Condensing Units

What differentiates a split system from other HVAC systems is that it is composed of an indoor air handler with the condenser and compressor in a metal enclosure outdoors. Unlike packaged units, the air handler with fan and evaporator coil is separate from the condenser and compressor. There are both single and multi split systems.

Single Split Systems

The single split system is a prevalent choice for business owners. They are affordable and compact, making it ideal for small offices, restaurants, shops and server rooms. Installation is much less than centralized units. Since they operate independently, the failure of any one unit to perform does not impact any other areas.

The single split HVAC system typically consisted of an air conditioner to cool and a furnace to convert the refrigerant. An evaporator coil circulates the air. The unit is controlled with a thermostat or similar control panel.

Multi Split Systems

Where single split units have one indoor unit for every outdoor unit, multi split systems can have accommodated up to nine indoor units for every outdoor unit. This is a more aesthetically pleasing choice and better for buildings with limited exterior space. However, because it requires more ductwork, installation is higher as compared to a single split system.

This configuration is highly energy efficient, using inverter technology to allow the compressor to operate at variable speeds. The highest energy usage in commercial systems comes from the compressor turning on and off. With the use of sensors and heat pumps, the multi split system can identify areas that need adjustment and move warm air from one area to another cooler area.

VRF Systems

Variable refrigerant flow or VRF HVAC systems are good choices for medium to large office buildings or hotels. There are two types of VRF systems. Heat pump VRF systems can either heat or cool, but it can’t do both simultaneously. It is appropriate for open floor plans. A heat recovery system is a better option for multiple rooms or offices, as it can provide heat to one while cooling another at the same time.

Direct Fired Air Handlers

These heavy-duty air units are built to last with the base, frame and wall panels welded into one unibody cabinet. They are energy efficient, delivering 100% of the burner power into the heated space. Indoor air quality is maintained by the introduction of fresh outside air into the system. Up to 80% of the air can be recirculated, reducing your energy costs.

Indirect-Fired Air Handlers

Indirect fired or IDF air handling units pressurize an area with conditioned outdoor air. You have the option to heat, cool or recirculate the conditioned air. Carbon monoxide, a natural by-product of combustion, is directed outside the space during the heating mode. It is a highly energy-efficient option.

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

Features of an Industrial HVAC System

Some features that may be found in an industrial HVAC system include:

- Heating systems such as electric heat, boilers, furnaces and heat pumps

- Ventilation and dust collection

- AC units including rooftop units, direct expansion units, chillers and heat pumps

- Thermostats

- Sensors

- Automation systems

Heating, ventilation and air conditioning systems play an essential role in industrial operations. They condition the air for worker comfort and to safeguard mechanical and electronic equipment. The ventilation system is vital for filtering out dust, dirt, chemical and other contaminants from the air. Dust collection systems are frequently integrated into the overall HVAC system to improve and maintain air quality. By separating the air filtering, it allows the HVAC system to work more efficiently.

Ductwork is a critical component in any industrial HVAC system. Materials can include galvanized, stainless or rolled steel. The design, fabrication, operation and maintenance must consistently and reliably meet the regulations for air quality standards, as well as building codes. It also plays a role in maintaining a safe workplace. That’s why it is critical for you to choose from knowledgeable, experienced local HVAC contractors.

Sensors, thermostats and automation systems provide energy efficiency. Requirements for heating, cooling and ventilating an empty building can vary significantly from times when the facility is fully staffed and operating normally. Sensors can monitor air quality, temperature and occupancy, as well as air pressure to optimize system operations and notify maintenance when there is a problem.

Benefits of Using Experienced Local HVAC Contractors

The cost of using inexperienced installers can be significant. Poorly designed, fabricated or installed HVAC systems can use more energy, reduce productivity and result in low air quality. Substandard air quality can not only impact employee health that results in more frequent absenteeism, but if left unchecked, it could endanger lives and put your business at risk.

Advantages of using an industry-leading provider for sheet metal fabrication, installation, service and preventative maintenance needs include:

- Cost savings

- Improved air quality

- Superior energy efficiency

- Optimized design for your facility

- Certified, licensed professionals

- Adherence to regulatory requirements, building codes and industry standards

What to Look for in an HVAC Contractor

Commercial and manufacturing environments have very different needs for their HVAC systems than residential uses. Industrial HVAC systems can be very complex, depending upon the functions and the size of the facility. When your business is at stake, you can’t afford to take the lowest bid. You need to carefully vet your contractor and ensure that you get the expertise required for quality materials, installation and maintenance.

Lee Industrial Contracting is a 100% employee-owned company, meeting and exceeding our customers’ expectations with turn-key solutions for over 30 years. Our capabilities include:

- Installation of standby generators, including backup lighting panels, UPS systems and whole service backup power

- 24/7 emergency generator services available365 days a year

- Design and installation of primary power by certified electricians

- 24/7 emergency repair to minimize your downtime 365 days per year

- Specialists in control wiring, from wiring upgrades to complete machine rewire

- Comprehensive industrial installation, including electrical design, motor controls and transformers

- Monitoring of power quality, including monitoring equipment to help determine and repair power quality issues

- Infrared imaging to determine predictive maintenance

- Complete lighting installation for commercial and industrial applications

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

To the untrained eye, a commercial construction site and an industrial construction site may not look very different. In fact, most people use the terms interchangeably. Professionals who work in both construction types know there are challenges and processes that are unique to each type. The key is looking beyond the obvious similarities to find the specific factors that set them apart.

Permitting Process

Most big construction projects require some type of permitting. In some jurisdictions, even putting up a sign may attract the legal attention of local officials. Commercial construction permitting tends to focus on zoning requirements, general safety and occupancy requirements. Once met, a business can open its doors with ease.

Of the two construction types, industrial sites have more compliance factors to take into consideration. This is especially true if the company handles, stores or manufacturers hazardous material. Satisfying these guidelines, in addition to commercial guidelines, can tack on weeks or months to the process. It may also necessitate specialized expertise.

Site Planning

Once construction companies have the green light to start working, it’s time to create a plan for how the construction site will play out. At this point, the lead contractor will meet with the client to determine what the most important concerns are. Engineers will then need to determine the best way to work around these design flaws.

Both construction types want to limit how construction affects operations as much as possible. The difference is in the how. Commercial construction site planning focuses on keeping businesses accessible to customers and presentable to the public. Industrial construction sites are less concerned about being presentable and more focused on logistics, such as power consumption allocation.

Design Process

The design process is one of the most exciting parts of the project for the client and the contractor. It allows both parties to blend needs and wants and bring ideas to life. However, the design language for a business frequented by the public or consumers is much different from the industrial design language. The fact that many commercial spaces are taking on industrial aesthetics does little, if anything, to change this.

For both construction types, traffic flow is important, but the reasons are different. Commercial construction sites need to prioritize the easy and functional flow of traffic to maximize how long customers spend in spaces and encourage lingering. Industrial construction designs favor floorplans that prioritize the following:

- Keeping traffic moving

- Reducing lingering

- Enhancing productivity

- Improving efficiency

Infrastructure Support

Commercial construction sites do not differ terribly from how homes are constructed. In fact, some commercial construction sites are for long-term or short-term residential use, such as hotels, nursing homes and apartment buildings. The infrastructure generally includes HVAC systems, the ability to control smaller ecosystems within the whole and some provisions for larger power consumption.

Of the two construction types, manufacturing requires the strongest supporting infrastructure. This includes not just provisions for massive power consumption, but also waste management. This can drastically change the materials and expertise required.

Project Management

Most project managers can handle the average commercial construction site. The contractors they hire may also not differ much from what is required for larger residential projects. For instance, project managers may need to focus on organizing plumbers, electricians and interior designers.

Both construction types require these skill sets, but industrial construction sites also require advanced and specialized skills. These may include large-scale installations, equipment assembly and custom fabrication. Project managers may also need to handle the complex logistics systems that may become necessary to move oversized loads when plants expand or move locations.

Without a doubt, industrial and commercial construction sites are very similar. Even so, the main distinguishing factors for both construction types can all be tied back to priorities, functions and logistics.

Receive your free quote today or call us today at (888) 833-8776 to learn how we can complete your next industrial project.

Subscribe and receive updates via email

When it’s time to add a generator or build out a new department, you want a seasoned, full-service electrical contractor who can handle the project from start to finish. Lee Industrial Contracting is eager to help you define the scope of your electrical work and take care of every detail until you sign off on the final phase of the job.

For over 30 years, Lee has led the industry in safe, efficient, turn-key electrical solutions. Each time we begin a project, we recommit to the essential framework that guides our business: to provide our clients with the finest people, materials and equipment available.

In-House Resources

Industrial electrical contractors often depend on numerous outside resources, which means time lost to scheduling and coordination. From in-house skilled trades to vehicle fleets and specialized equipment, Lee keeps an extensive supply of resources all under one roof. You can count on the latest, state-of-the-art equipment and practices, and you won’t be left waiting for a part or a sub-contractor to arrive.

Services

As leading industrial contractors for over three decades, Lee enjoys working across industries and applications to offer a wide range of electrical services. Our master electricians can handle whatever scope of service you require, from regular plant maintenance to major renovations and installations. Not all industrial electrical contractors offer our range of new installs, upgrades and emergency services. Our commercial and industrial capabilities include:

- Primary power – design and installation

- Power upgrades – partial or whole operation

- Backup power – standby generators, lighting, UPS systems

- Control wiring – upgrades to complete machine rewires

- Emergency generator repairs – 24 hours, 365 days

- Motor controls and transformers – design and installation

- Power quality monitoring – identify and repair

- Infrared Imaging – determine predictive maintenance

Whatever your industry, our versatile teams are ready to take care of your unique project parameters.

Dedicated Support

Right from the start, our teams shift into high gear to get your project off the ground swiftly. We provide you with a full-time, dedicated project manager to coordinate on-site activities and streamline communication.

Industrial electrical contractors don’t always slow down long enough to listen. We train our project managers to listen. Your vision is essential in helping us define a successful schedule and budget plan. You can trust your dedicated manager to monitor efficiency and budget adherence throughout your project.

Safety

We know you count on your electrical contractor to adhere to the highest safety standards. Safety isn’t just a part of our business at Lee Industrial; it permeates every aspect of our work. Our people know we value their safety. We begin training our employees on safe equipment operation from their first day on the job. Our managers ensure every worker and supervisor understands the safety risks specific to your job or location.

Industrial electrical contractors must stay aware of ever-changing safety standards. Our electricians regularly monitor code changes and OSHA regulations to keep your people and ours safe. In addition, Lee’s preventative maintenance program minimizes safety-related downtime, keeping your job moving smoothly and on schedule.

Employee Training

Lee’s new hires understand our high standards for safety and quality workmanship. Our apprentices work directly with our master electricians and journeymen to hone their skills. At the same time, they gain additional theoretical and technical knowledge from Michigan State University’s electrical apprenticeship program. We invest in our employees because we know they are the face of our commitment to excellence on every job we complete.

Industrial electrical contractors have the challenge of keeping many balls in the air. Lee Industrial Contracting understands your bottom line depends on continuity, and we pride ourselves on keeping your operation moving forward. Our 24-hour availability and extensive on-site resources enable us to mobilize quickly and guarantee minimal downtime. We are eager to exceed your expectations. When you think of cutting-edge electrical contractors we hope you think of Lee Industrial Contracting, your source for efficient, affordable, reliable electrical work.

Start Your Project Today

Compare foundations for steel buildings today with our team at Lee Industrial Contracting. Schedule a conversation with our professional team today to discuss your steel structure needs, your local area and your foundation preference. We offer state-of-the-art solutions that ensure workplace safety and long-lasting support.

Subscribe and receive updates via email

When you have a 300-ton-capacity crane on your jobsite, it’s important to know your industrial contractor cares about safety as much as you do. Jobsite safety is a leading business value at Lee Industrial Contracting, and our turn-key solutions for safe industrial work have served our customers well for more than 30 years.

Safety Vision

Whether you need heavy industrial equipment transport, a warehouse concrete pour, or a whole power-plant renovation, our customer-focused account managers work closely with you to ensure your safety parameters become our safety parameters. Our trained staff can evaluate your own site standards and integrate them into our preventive model. Here’s how our safety vision can make a difference to you and your company’s bottom line:

- Lee Industrial Contracting values the success of your business like we value our own. Our commitment to jobsite safety is intended to prevent employee accidents and injuries while providing you with the best equipment and services in the industry.

- Your safety record is an important measure of your organization’s work quality and professionalism. As an industry expert in workplace safety, Lee can help you maintain a favorable safety-incident rating.

- Lower operating costs are a welcome consequence of our effective safety practices. We are happy to pass those savings on to you.

We have earned an industry-wide reputation for safe, quality products and services. In 2019, General Motors leadership named Lee Industrial Contracting a GM supplier of the year for the second year in a row.

Jobsite Safety

Our high standards for safety protect our personnel and yours on the job. Safe practices depend on proper planning, quality control, and efficient organization. Our commitment to a safe working environment is noticeable right away. Lee project managers choose only the highest quality equipment and maintain a clean, efficient job site at all times. We are proud to employ our own preventive maintenance program for our in-house heavy-equipment fleet. Lee personnel are trained to do everything possible to prevent safety incidents while still maintaining scheduling deadlines.

Leadership Goals

Lee Contracting leadership prioritizes safety at every turn, both during transport and at your jobsite. Our managers evaluate each project to ensure we meet our standards for jobsite safety. With accident prevention being the goal, our managers work with you and your team to pre-identify potential safety risks specific for your project, equipment and job location.

Staying abreast of current industrial safety violations and trends helps us define our safety platform. Our managers monitor the top safety violations identified by the Occupational Safety and Health Administration. OSHA’s list informs our safety team of future training topics and provides important information about problems that may arise with new equipment or processes. You can trust Lee’s leadership and professionals to stay ahead of potential concerns and be prepared to troubleshoot any unexpected challenges with jobsite safety.

Empowered Workforce

Safety culture starts early at Lee Industrial Contracting. We believe in empowering our personnel and trusting them to make good safety decisions. Our new hires begin their employment learning strong safety values. We train them to recognize unsafe job site conditions and the potential for injury. All Lee personnel who are involved with your project will have been briefed on potential site-specific hazards for your job. Our commitment to safety means fewer delays, better service, and reduced costs for you.

Heavy industrial work can be dangerous because of the large scale of the work and the weight and size of the equipment. Lee Industrial Contractors take Jobsite safety seriously. It is woven into our corporate culture, our workforce, and our every business practice. We know both your organization and ours are healthier and happier when safety is prioritized at every level.

Start Your Project Today

Compare foundations for steel buildings today with our team at Lee Industrial Contracting. Schedule a conversation with our professional team today to discuss your steel structure needs, your local area and your foundation preference. We offer state-of-the-art solutions that ensure workplace safety and long-lasting support.

Subscribe and receive updates via email

Update your facility and grow your business with single-source contracting by Lee Industrial Contracting. As a global leader in turn-key solutions for projects, our team of technicians and state-of-the-art equipment is capable of delivering your plant relocation, restructuring or updating projects on an accelerated timeline. Explore our turn-key solutions today to see how we offer personalized planning and industry-leading services for your specific project needs.

Advantages of Single-Source Contracting

Communicating with a single team about a turn-key solution for your project leads to a range of benefits. When you work with a single-source contractor, you’ll enjoy controlled costs, accelerated timelines, minimal operational impact and straightforward project management.

Controlled costs means that since we self-perform all of the trades with our in-house employees, we can control the entire timeline of the project. This allows us to work on accelerated schedules and you don’t have to coordinate different stages of the project with multiple contractors.

Emergencies don’t just happen on the 1st shift. Our teams are available 24/7. So whether your needs are at 9 am, 8 pm or 3 am, our crews will be there for you.

Updating, relocating and repairing your manufacturing equipment often requires downtime. While this isn’t always possible to avoid, we work with your schedule and your operational deadlines to keep downtime at a minimum.

Convenient project management means you have a single point-of-contact for the entire project. A single, full-time project manager handles any requests, questions or concerns you may have. Your project manager will update you on the status of the project, so there won’t be any surprises as you prepare to utilize your new, updated or relocated equipment.

Project Capabilities

When you need a turn-key solution for projects around your industrial facility, you need a wide range of capabilities. Our primary capabilities include:

- Foundations

- Rigging

- Electrical

- Mechanical

- Fabrication

- Machine Repair

Our team is ready to discuss your unique project, whether is is installing -60-foot pits or moving equipment up to one million pounds, our equipment and skilled tradespeople have a diverse range of capabilities.

As your single-source contractor, we combine these capabilities to craft a turn-key solution for projects in your plant. Common projects include machinery moving, relocating a plant or restructuring a facility. Moving machinery allows you to replace an outdated system or service your equipment. We break your equipment down as little as possible to safely transport it with our dedicated rigging and transportation equipment.

Plant relocation services give you the freedom to move your entire production line anywhere in the Continental United States. Restructuring includes renovations, foundation improvements and machinery relocation to maximize the productivity and safety of your plant.

Our Contracting Process

We have a seven-step contracting process we use to deliver a turn-key solution for projects. Walkthrough each step with your own project manager to enjoy a completed project that exceeds your expectations:

- Strategic approach

- Project analysis

- Turn key opportunity

- Plan of action

- Submit proposal

- Project kickoff

- Customer satisfaction

It all starts with our strategic approach to your specific project. Our approach and the personalized analysis of your unique project come together as we craft a plan of action and proposal for your company.

Once approved, we kick off the project with the full support of our professional equipment and licensed contractors. We continue until you’re completely satisfied with your turn-key industrial solution.

Start Your Project Today

Schedule a conversation with our professional team today to discuss your unique project’s needs. We offer state-of-the-art solutions.

Subscribe and receive updates via email

All buildings regardless of purpose need a solid foundation. Create the reliable foundation your steel building needs with the help of Lee Industrial Contracting. Our foundations use the latest equipment and industry best practices to ensure a turn-key solution for your new facility. Discover how we can get your steel building construction project started quickly to expand your business or relocate your manufacturing process. Here are some of the most common foundation types we work with.

Perimeter Footing

This durable and affordable type of foundation uses a poured concrete exterior wall to support the entire structure. Also known as a perimeter wall, this construction project is one of the most basic foundations for steel buildings. Use it to support the entire weight of your building or use it in conjunction with concrete slabs or piers for versatile support.

Floating Foundations

One of the most popular foundations for steel buildings is the floating slab. Also known as a slab foundation, this type uses a continuous grade beam slab to support a structure. It can be poured under a column or used to reinforce the vertical weight of columns.

This type of foundation is suited to wet areas where soft soil would otherwise be an issue. It requires less digging and typically doesn’t require footings or piers to support the weight of your steel structure. Additional preparation is required to run electrical and plumbing lines before the foundation is poured.

Pier, Footing and Grade Beam Foundations

Pier and beam foundations are ideal for situations where soil movement may be an issue. Pavilions, riding arenas and agricultural buildings often use pier, footing and grade beam foundations as a solid base with versatility. These foundations for steel buildings start with rectangular or square footings with piers resting on them. A grade beam wall provides support for the structure. Some piers are drilled instead of being secured with footings.

Unlike a slab foundation, this option leaves the floor open for a dirt or gravel option without compromising the durability of the structure. It can be more expensive than other options, so it’s generally reserved for buildings that use a dirt or gravel floor.

Portable Foundations

If you need to transport your structure, our team at Lee Industrial Contracting can assist you with the foundation, construction and transportation of your building. A portable foundation uses industrial plates anchor bolted to a concrete perimeter. Once you’re ready to transport your structure, simply unbolt it and prepare it for rigging and transportation.

Steel Building Foundation Considerations

There are a number of factors you need to consider when comparing foundations for steel buildings. Thankfully, our engineers are experienced with a wide range of foundation projects. Here are some factors our team can address with you to find the ideal foundation for your structure:

- Land

- Load

- Weather

What does your building site look like? Soil qualities, climate and grading can all affect the type of foundation you need. Work with an engineer at your build site before settling on a specific type of foundation.

Many steel structures are taller than timber frame structures, so it’s important to have a secure foundation. Discuss your building height, weight and other characteristics with an experienced engineer. Unusual shapes, heavy-duty equipment and other features impact the foundation selection, so be sure to communicate your business goals and the intended use of your steel structure while comparing foundation types.

Finally, wind, rain and frost are serious factors in steel building construction. Extreme wind uplift, the freeze/thaw cycle and heavy rain can all impact the foundation design and construction. Work with a leader in commercial foundation construction to prevent weather-related damage.

Start Your Project Today

Compare foundations for steel buildings today with our team at Lee Industrial Contracting. Schedule a conversation with our professional team today to discuss your steel structure needs, your local area and your foundation preference. We offer state-of-the-art solutions that ensure workplace safety and long-lasting support.