Tag: safety

The extreme cold weather during winter can make it difficult for employees who work outside to stay warm throughout the day. Taking the necessary precautions to stay warm can avoid the risk of developing several types of cold stress including: hypothermia, trench foot, or frostbite. Make sure to follow these tips to stay safe and warm while working outside this winter:

1. Wear layers of clothing

When working outside, it’s important to dress in layers to stay warm. Wear quality warm clothing such as thermal undergarments, insulated pants, coats and overalls. Make sure that your layers are long enough to cover your waist when you are bending or reaching while working. All clothing should allow adequate blood flow. If you get sweaty, consider removing a layer because inactivity after sweating can cause you to become cold again. To keep your feet warm, double up on socks and make sure your boots are thick and properly insulated.

2. Wear gloves

2. Wear gloves

When working outside, choose gloves that will protect your hands from the wind and that have good insulation. Some fabrics, like leather, are very helpful in blocking the wind, and the thin, insulated layer allows you to move your fingers while remaining warm.

3. Keep your feet and head covered

Cold weather can be especially harmful in these areas. Wear insulated and water-resistant boots, as well as a warm hat and, if necessary, a facemask. Make sure your ears are covered.

4. Keep moving

Moving around, even on your downtime, will help you to stay warm. Do some form of physical activity, such as stretches, jumping jacks or walking.

5. Work together

It is a good idea to work in pairs or a team when working in the extreme cold. This allows your coworkers to watch for the initial subtle symptoms of cold stress. Intense shivering and confusion are among the most common signs of cold stress.

6. Consume hot beverages & eat a warm lunch

Drinking warm beverages like coffee and tea throughout the day will help to keep you warm and fight the cold-induced lethargy. Eating a warm lunch will help warm your body up and keep you warm as you continue to work through the rest of the day.

By taking the necessary precautions to stay warm while working outside during the winter, you will be able to lower your risk of hypothermia, trench foot and frostbite. Our safety department ensures that our employees are prepared to work outside in all weather conditions.

Call us today to receive a free quote for your next industrial project, (888) 833-8776.

Subscribe and receive updates via email

Working in the construction industry usually means working in a loud environment. Wearing the correct personal protective equipment is necessary for all job sites from working in automobile plants to our own in-house machine shop. Protecting your hearing should be no different. Controlling noise level can be broken down to a three-step process:

Reduce: Reduce noise by using the quietest equipment available.

Move: Move the loud equipment farther away. Noise levels go down as we increase the distance from the object. If you are not required to work in that area, move to a quieter area.

Block: Block the noise by building temporary barriers.

You may think that long-term exposure is needed for damage to occur to an individual’s hearing, but it only takes 1 hour per day around loud noises like a jackhammer or stud welder for damage to occur. Some specific ways to limit exposure:

- Use prefabricated noise barriers

- Limit the hours worked in hazardous noise areas

- Use hearing protection to supplement noise reduction

Safety inspectors measure sound or noise levels using a device called a sound level meter. OSHA recommends that workplace noise levels be kept below 85 dBA as an 8-hour time-weighted average. As the noise level increases, it damages your hearing quickly.

At Lee Contracting, safety is our number one priority. We are continuously training our employees to recognize unsafe working conditions to minimize risk and the potential for injury. Our commitment to safety and health is designed to prevent employee accident/injury while promoting a positive environment. When our company meets all its safety goals, it translates to better service and reduced costs for all our customers.

Call us today to receive a free quote for your next industrial project, (888) 833-8776.

Subscribe and receive updates via email

Lockout/tagout refers to the procedures which keep employees safe from energized machinery and equipment.

Why are lockout/tagout procedures so important? Lockout devices hold energy-isolation devices in a safe or off position. They provide protection by preventing machines or equipment from becoming energized because they are positive restraints that cannot be removed without a key. Tagout devices are prominent warning devices that an authorized individual fastens to energy isolating devices to warn employees not to reenergize the machine.

If these procedures are not followed, employees can be seriously injured. At Lee we follow all OSHA standards to ensure the safety of our employees. How do we make sure our employees are safe? We follow our safety manual and hold mandatory training seminars upon employment. Some of our requirements are:

- Each authorized employee has the proper number of locks and devices to be able to perform proper lockout/tagout for the machines and equipment that they may be working on.

- All lockout or tag out devices must be affixed to each energy isolating device and indicate the name of the employee applying the device.

- Lockout devices must be affixed in a manner to hold the energy isolating device in a safe or off position.

- Tag out devices used with energy isolating devices with the capability of being locked out shall be fastened at the same point at which the lock would have been attached. If a tag cannot be directly attached to the energy isolation device it shall be located as close as safely as possible to the device in a position that will be immediately obvious to anyone attempting to operate the device.

- Each energy source must be locked out completely isolating the equipment.

These are only some of the items we follow to prevent injury. In keeping with our pledge to safety and health, we employ a safety manager with extensive experience in the development and maintenance of world-class programs. Our safety manager works closely with administrative and field personnel to ensure the company meets or exceeds safety regulations. With our mix of highly experienced safety representatives and our safety policies, we provide first-class services and first-class safety to our customers.

These are only some of the items we follow to prevent injury. In keeping with our pledge to safety and health, we employ a safety manager with extensive experience in the development and maintenance of world-class programs. Our safety manager works closely with administrative and field personnel to ensure the company meets or exceeds safety regulations. With our mix of highly experienced safety representatives and our safety policies, we provide first-class services and first-class safety to our customers.

Learn more about our safety department today.

Call us today to request a free quote on your next industrial project, (888) 833-8776.

Subscribe and receive updates via email

Lee Contracting prides itself on keeping employees, customers and guests safe at all times. We provide extensive safety training to ensure that everyone makes it home. While certain trainings are site-specific, we offer an array of courses multiple times a year to all field staff.

Many companies now require an OSHA 10 or OSHA 30 card to work in their facilities and it is Lee’s responsibility to ensure our entire staff is provided the training required. These trainings focus on hazard identification, avoidance, control and prevention. OSHA courses include:

- Intro to OSHA

- General Safety and Health

- Fall Protection

- Electrocution Hazards

- Caught In or Between

- Struck By: Falling objects, trucks, cranes

- PPE

- Health Hazards in Construction

- Hazcom1

- Cranes and Derricks

- Excavations

- Materials Handling

- Scaffolds

- Stairways and Ladders

- Tools

- Concrete Masonry and Construction

- Confined Space Entry

- Fire Protection and Prevention

- Steel Erection

- Welding and Cutting

- Motor Vehicles

- Powered Industrial Trucks

- DOT Placarding

- Electrical

- Lockout Tagout

- HazCom 2

Crane certification courses for both mobile cranes and overhead cranes are also provided. Lee is one step ahead with offering this training before OSHA implements certification requirements in November of 2018. Anyone working on and/or around cranes needs to be certified as an operator, rigger and signal person. The certification requires the student to pass The National Commission for the Certification of Crane Operators (NCCCO) test.

CPR/First Aid training and certification is offered to ensure that our employees are prepared for an emergency in any setting. Lee provides CPR/First Aid training to all employees while MIOSHA only requires one individual on site to be certified.

Lee Contracting’s culture is based around safety. Learn more about our safety program on our website today.

Call us today to receive your free quote on your next industrial project (888) 833-8776.

Subscribe and receive updates via email

Falls from portable ladders are one of the leading causes of occupational fatalities and injuries. Ladders, when used effectively, make our jobs easier and when used improperly, potential hazards may arise; therefore, it is important to ensure that everyone is trained to recognize and avoid unsafe working conditions to minimize the risk of an incident/injury.

Falls from portable ladders are one of the leading causes of occupational fatalities and injuries. Ladders, when used effectively, make our jobs easier and when used improperly, potential hazards may arise; therefore, it is important to ensure that everyone is trained to recognize and avoid unsafe working conditions to minimize the risk of an incident/injury.

Below are some guidelines that will help you identify and minimize hazardous conditions when using portable/extension ladders.

Inspect your equipment

- Look the ladder over well before you start up. See anything wrong? Bent or missing rungs? Grease or heavy rust on rungs or rails?

- Is the ladder properly labeled with the company name and/or logo?

- Are all locks on an extension ladder properly engaged?

- Understand the limits of the equipment you are using

- Always select the correct ladder for the work being performed

- Follow the manufacturer’s instructions

- Do not exceed the maximum load rating of a ladder

- Be aware of your surroundings

- Use a ladder only on a stable and level surface, unless it has been secured (top or bottom) to prevent displacement

- Avoid electrical hazards, look for overhead power lines before handling a ladder

- Avoid using a metal ladder near power lines or exposed energized electrical equipment

Know your numbers

- A portable extension/leaning ladder shall be set up so the horizontal distance from the top support to the base is 1⁄4 of the vertical distance (1:4 ratio)

- The minimum distance for metal ladders around energized electrical lines is 20 feet

- Minimum distance for other than metal is 10 feet for up to 50kV and 0.4 inches per kV thereafter

- An extension or straight ladder used to access an elevated surface must extend at least 3 feet above the point of support

Body Positioning

- Always maintain a 3-point (two hands and a foot, or two feet and a hand) contact on the ladder when ascending and descending

- Always face the ladder when ascending/descending

- Maintain your balance and center of gravity by keeping your belt-buckle/belly button between the two uprights and/or side rails

- Do not use the top step/rung of a ladder

At Lee Contracting, we make safety our number one priority. We are continuously training our employees to recognize unsafe working conditions and to minimize risk and the potential for injury. Our commitment to safety and health is designed to prevent employee accident/injury while promoting a positive environment. When our company meets all of its safety goals, it translates to better service and reduced costs for all of our customers.

Subscribe and receive updates via email

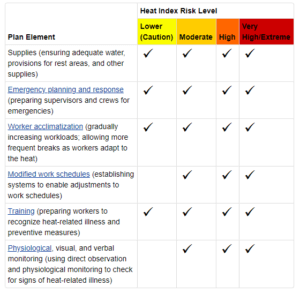

Summer has arrived and working in high temperatures can cause major health issues if the correct precautions are not taken. With high air temperatures, radiant heat sources, high humidity, direct physical contact with hot objects or strenuous physical activities, there is a high potential for heat stress. When the body is unable to cool itself by sweating, several heat-induced illnesses such as heat exhaustion and stroke can occur and can result in death.

Factors Associated with Heat Stress

- High temperature and humidity, direct sun exposure, no breeze or wind

- Low liquid intake

- Heavy physical labor

- Waterproof clothing

- No recent exposure to hot workplaces

Symptoms of Heat Exhaustion

- Headache, dizziness, or fainting

- Weakness and wet skin

- Irritability or confusion

- Thirst, nausea, or vomiting

Symptoms of Heat Stroke

- May be confused, unable to think clearly, pass out, collapse, or have seizures(fits)

- May stop sweating

What to Do for Heat-Related Illness

- Call 911 or the designated emergency number for your site

- Move the worker to a cool, shaded area

- Loosen or remove heavy clothing

- Provide cool drinking water

- Fan and mist the person with water

Heat-related illnesses can be prevented if the right precautions are taken. Safe work practices to reduce the chance of a heat-related illness include work/rest cycles, drinking water even if you are not thirsty, wearing light-colored clothing and building up a tolerance to working in the heat.

Heat-related illnesses should not be taken lightly, it can become a very serious situation in a short amount of time. Please look out for one another. If something doesn’t feel right, it’s probably not. Be safe, stay hydrated and keep cool.

Lee’s training programs and commitment to safety keeps everyone safe on the job site. Learn more about our safety team & safety training today.

Call us today to request a free quote on your next project, 888.833.8776.

Subscribe and receive updates via email

Electrical safety should be a continuing priority for every employee. Worksites are full of electrical safety hazards that must be observed. Basic ‘lockout/tagout’ and ‘test before touch’ procedures apply to every job. As industrial manufacturing plants get busier, it seems that open/free space always decreases. Per OSHA statistics, electrocutions account for 8.3% of construction deaths and control of hazardous energy (lockout/tagout) was the 5th most frequently cited OSHA standard in 2017. Employers and workers alike must work together to improve safe work practices and decrease the number of injuries and deaths caused by electrical accidents.

Free space in front of electrical equipment not only makes it easier to work, but it is also required. These requirements become a safety hazard when they are infringed upon by stored equipment and/or manufacturing materials. This space is designed to keep workers safe while completing electrical maintenance or upgrades. Care should be taken to protect yourself when working in these areas.

Before starting work, establishing an electrical shutdown plan or isolating the equipment should be the first topic of discussion. Per OSHA guidelines, electrical equipment must be de-energized before work is performed. With the customer having ample time to schedule the shutdown, work can be performed without major interruption to their facility. Limited approach boundaries and caution tape must also be set up per the National Fire Protection Association. The boundaries must be maintained while work is being performed.

Performing electrical work in unsafe conditions is never permitted. Remember that electrical hazards can be avoided if these policies &  procedures, among other policies, are followed.

procedures, among other policies, are followed.

Lee’s training programs keep our electricians safe on every job. To learn more about our electrical team, visit our website. Safety of our personnel and customers is always our top priority.

Call us today to request a free quote on your next industrial electrical project, 888.833.8776.

Subscribe and receive updates via email

Electricity is essential on every one of our job sites. It is sometimes called the “silent partner” on the job. It supplies the power needed to run tools and machines, it provides lighting, and it powers heaters and air conditioning units. When used safely and properly, electricity makes our lives easier.

Electricity is essential on every one of our job sites. It is sometimes called the “silent partner” on the job. It supplies the power needed to run tools and machines, it provides lighting, and it powers heaters and air conditioning units. When used safely and properly, electricity makes our lives easier.

Electricity has also been called the “silent killer” because you don’t hear, see, taste, or smell it. If you use electricity carelessly or recklessly, if you overlook the many hazards it presents, you may be setting yourself up for injury or death from burns, falls, shocks, or electrocution.

To protect yourself from the hazards of electricity, keep the following safe work practices in mind:

- Visually inspect electrical hand tools and extension cords before each use.

- Immediately remove defective tools and cords before using.

- Always wear the necessary PPE and use grounded or double-insulated tools.

- Never handle an electrical tool by its power cord.

- Only use extension cords that are rated for hard or extra hard use. Codes like S, ST, SO, STO, SJ, SJT, SJO & SJTO should be printed on the cords.

- Take care of extension cords. Keep them out of the way to prevent damage.

- Never yank cords to disconnect them. Reach down and pull the plug from the receptacle.

- Don’t try to repair electrical cords or tools unless you are qualified and authorized to do so. Repairs should only be made by qualified electricians.

- If you are authorized to make repairs, make sure you follow lockout/tagout procedures.

- When working in damp or wet areas, only use tools protected by a ground-fault circuit interrupter (GFCI).

- Never operate electrical tools or equipment while standing in water.

- Never use makeshift wiring.

- Use 3-prong receptacles. Never break off the ground to fit an underground outlet.

- Keep equipment and activities at a safe distance (at least 10 feet) when working around power lines.

All of our electricians attend classes in NFPA 70E and MIOSHA Parts 33 & 40 “Electrical Safe Work Practices” instructional programs to ensure we are doing everything we can to prevent electrical injuries. We design, quote, layout, and execute electrical installations to follow electrical safe work practices. We provide high levels of PPE and test equipment for protection.

All of our electricians attend classes in NFPA 70E and MIOSHA Parts 33 & 40 “Electrical Safe Work Practices” instructional programs to ensure we are doing everything we can to prevent electrical injuries. We design, quote, layout, and execute electrical installations to follow electrical safe work practices. We provide high levels of PPE and test equipment for protection.

Whether you are at home or at work working with electricity remember to practice electrical safety and keep electricity as a silent partner in your projects.